Written by Anneri Fourie | Crises Control Executive

Downtime in Manufacturing: The Problem That Costs More Than You Think

For manufacturers, downtime is never just about machines coming to a stop. Every minute a production line is idle, costs spiral far beyond lost output. Industry research suggests that unplanned downtime costs large manufacturers over £200,000 per hour. For high-volume industries such as automotive, aerospace or chemicals, the number can be even higher.

These costs are not limited to the obvious hit to production. Delays ripple across supply chains, create knock-on costs for logistics, damage customer trust, and can even trigger regulatory investigations. A single failure can quickly move from being an operational issue to becoming a financial, reputational, and safety crisis.

The solution is not only better maintenance or more investment in equipment. The way a manufacturer responds to incidents often determines the true scale of the damage. This is where incident management software makes the difference, helping organisations reduce disruption, improve safety, and strengthen continuity.

The Real Cost of Downtime in Manufacturing

Unplanned downtime can be triggered by many factors: equipment failure, IT outages, power cuts, fire alarms, safety incidents, cyberattacks, or even access restrictions within the site. While the immediate effect is clear – a pause in production – the hidden costs can be just as severe:

- Safety exposure: Equipment failures or chemical spills put workers at direct risk.

- Regulatory fines: Laws such as the UK Health and Safety at Work Act, EU Seveso III Directive, or OSHA in the US require accurate records of incidents. Missed documentation can mean penalties.

- Customer impact: Missed deadlines and order delays damage trust and can lead to financial penalties.

- Reputation damage: Frequent or poorly managed downtime affects confidence among clients and investors.

- Employee morale: Confusion during downtime reduces confidence in leadership and lowers productivity.

Even the best maintenance strategies cannot eliminate downtime completely. What separates resilient manufacturers from vulnerable ones is how they communicate, coordinate, and recover during disruption.

Why Traditional Response Methods Slow You Down

Many plants still handle downtime with outdated communication methods. Supervisors send group emails, engineers rely on phone calls, and managers chase updates across multiple systems. This approach wastes valuable time and increases the chance of mistakes.

The traditional model has three main weaknesses:

- Slow communication: Not everyone receives alerts quickly, especially shift workers or contractors.

- Poor escalation: If the first response team misses an alert, the issue may sit unresolved.

- Lack of visibility: Managers cannot see who is responding or what progress is being made.

Without a structured response, downtime lasts longer, reporting is incomplete, and safety or compliance gaps emerge.

How Incident Management Software Reduces Downtime in Manufacturing

Incident management software brings everything into one place. It provides the tools to identify, notify, respond, and report incidents with speed and accuracy. For manufacturing, this means less confusion, shorter downtime, and better compliance.

Rapid Notifications with Mass Communication

Integrated mass notification software for manufacturing allows alerts to be sent across SMS, email, app notifications, and even social media at the same time. Staff receive updates instantly, whether they are on the production floor, in a control room, or offsite.

Escalation Workflows

If a team fails to respond within a set timeframe, alerts are automatically escalated to backup teams or managers. This prevents issues from stalling and ensures accountability.

Task Assignment and Real-Time Tracking

Tasks can be allocated directly within the system, with progress tracked on a central dashboard. Managers can see what actions are pending, who is responsible, and expected resolution times.

Audit and Compliance Support

Every step is logged, creating a detailed record of actions taken. This is essential for regulatory compliance under UK COMAH, EU Seveso III, OSHA in the US, or Canada’s Labour Code. Reports can also be used to demonstrate safety measures to insurers or auditors.

With these features, manufacturers can move away from firefighting and towards proactive resilience.

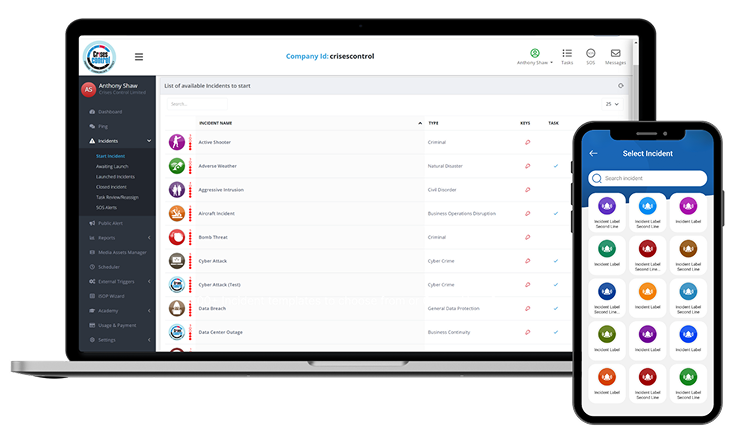

Interested in our Incident Management Software?

Launch and manage incidents in seconds with real-time dashboards, task management, multi-channel alerts, and mobile access for seamless response.

Using Mass Notification Software to Minimise Unplanned Downtime

Not every incident is catastrophic, but even smaller interruptions add up. Localised IT failures, temporary access restrictions, or small fire alarms can still cause costly production delays.

Using mass notification software to minimise unplanned downtime allows teams to act quickly before minor problems become major ones. Examples include:

- Informing staff about IT outages affecting production systems.

- Alerting workers about restricted access routes within the facility.

- Coordinating evacuation during a small-scale fire alarm.

- Communicating temporary system downtime for maintenance or testing.

By reducing confusion and wasted time, these notifications help keep operations on track.

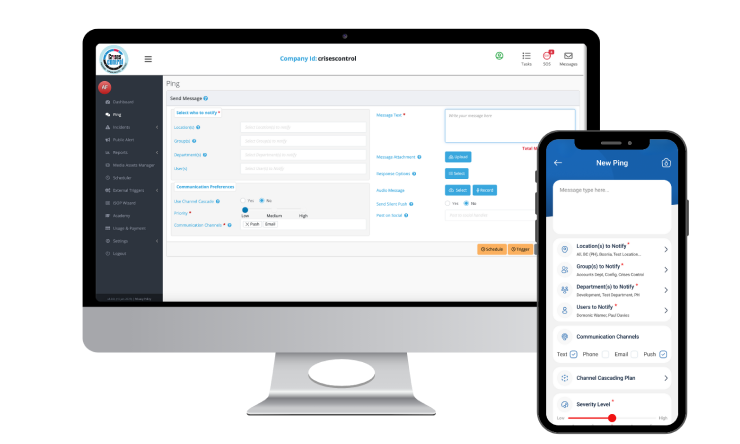

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Manufacturing Continuity Planning with Crises Control

True resilience requires more than fixing machines when they break. Manufacturers need continuity planning that covers all types of incidents.

Crises Control supports manufacturing continuity planning through:

- Incident simulations: Run drills for cyberattacks, chemical spills, or fires to prepare staff and identify weaknesses.

- Visitor and contractor safety: The QR Code feature ensures everyone on site can be registered quickly and included in alerts.

- Public alerting: Notifications can be sent to affected local areas during larger emergencies, with privacy protection built in.

- Data-driven improvement: Reports after each incident highlight response times, communication effectiveness, and areas for improvement.

By building these processes into operations, manufacturers can respond faster, protect workers, and comply with industry regulations.

Take Control of Downtime Before It Costs You More

Downtime affects more than just production. It can put workers at risk, disrupt supply chains, and impact regulatory compliance and customer trust.

Incident management software with integrated communication tools helps manufacturers respond faster, keep staff safe, and maintain operations.

Crises Control combines these capabilities into a single platform designed for manufacturing continuity.

Contact us today to see how Crises Control can reduce your downtime risk and strengthen your continuity planning.

Request a FREE Demo