Written by Anneri Fourie | Crises Control Executive

Communication Breakdowns Put Manufacturing Plants at Risk

Manufacturing plants are complex environments with multiple teams, machines, and processes working together. When communication fails, even small incidents can escalate quickly. A delay in notifying the right people can lead to production interruptions, safety incidents, regulatory issues, and damage to the plant’s reputation.

Mass notification software provides a centralised system for sending urgent messages to staff, contractors, and visitors. With clear, rapid communication, plants can respond to emergencies effectively and prevent minor issues from becoming major disruptions.

The Hidden Dangers of Poor Communication

Manufacturing plants face several communication challenges:

- Shift work and multiple locations: Teams may be spread across large facilities or different sites, making it hard to alert everyone at once.

- Complex safety risks: Handling chemicals, operating heavy machinery, and managing fire hazards means any delay in communication can be dangerous.

- Contractors and visitors: Temporary staff or visitors may not be included in standard communication channels, creating gaps in safety coverage.

- Regulatory compliance: In the UK, EU, US, and Canada, regulations require timely reporting and clear communication during incidents affecting safety and operations.

Traditional methods such as phone calls, emails, or walkie-talkies are often slow and fragmented. Without real-time updates, teams may act late, make mistakes, or miss critical information.

How Mass Notification Software Solves These Problems

Mass notification software for manufacturing plants ensures that urgent messages reach the right people quickly, reducing risk and maintaining production efficiency.

Rapid Multi-Channel Alerts

The software can send messages simultaneously across SMS, email, push notifications, phone calls and desktop alerts. Staff on the production floor, supervisors in control rooms, and offsite managers receive updates at the same time, which prevents confusion and ensures everyone knows what is happening.

Two-Way Communication

Workforce alert systems allow employees to respond to notifications. Staff can confirm their safety, report an issue, or provide status updates. Real-time feedback gives management an accurate view of the situation and helps teams act quickly.

Escalation and Accountability

If a message is not acknowledged within a set time, the alert is automatically escalated to backup teams or management. This ensures no incident is overlooked and that responsibilities are clear during critical events.

Role-Based and Location-Specific Messaging

Alerts can be tailored to specific roles or locations. Only relevant staff receive notifications, which reduces unnecessary confusion and ensures that action is taken where it is needed most.

Integration with Emergency Systems

Mass notification software integrates with existing systems such as IT monitoring, security, and facilities management. This allows all teams to coordinate seamlessly during an incident, preventing delays caused by disjointed communications.

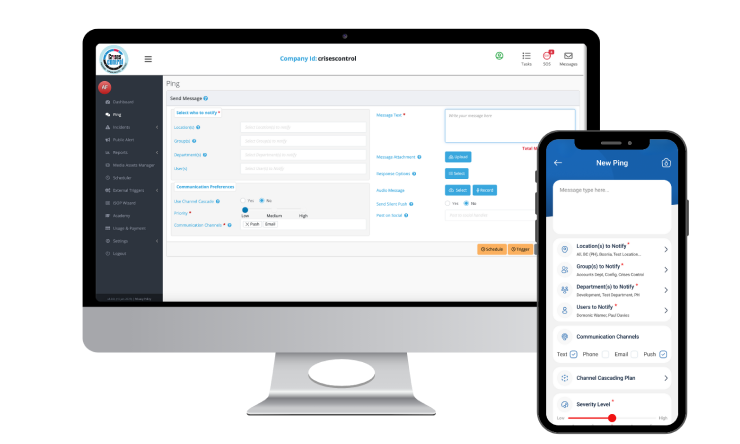

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Real-Life Situations Where Communication Breakdowns Cause Risk

- Chemical Spills or Fires: If staff are not alerted immediately, evacuation routes may not be followed correctly, putting people in danger. Mass notification software sends instructions instantly to all affected areas.

- IT or System Failures: Critical production systems can stop unexpectedly. Alerts ensure IT teams and operational managers respond quickly, reducing downtime and avoiding further operational impact.

- Contractor or Visitor Safety: Temporary workers and visitors may be unfamiliar with safety procedures. With QR code registration integrated with mass notification software, all site occupants receive instructions during emergencies.

- Minor Incidents Escalating: Small issues such as blocked access routes or equipment faults can quickly turn into major problems if staff are not informed promptly. Mass notification software ensures rapid action, preventing escalation.

Best Practices for Crisis Communication in Manufacturing

Manufacturers can strengthen their response by combining mass notification software with clear processes:

- Predefined Alert Protocols: Establish workflows for specific incident types, so alerts reach the right teams immediately.

- Regular Drills and Simulations: Test communication procedures to identify gaps and improve response times.

- Multi-Channel Messaging: Use SMS, email, app notifications, and desktop alerts to reach all staff efficiently.

- Audit and Reporting: Automatically log all messages and responses for regulatory compliance and post-incident review.

These steps ensure that communication is clear, fast, and reliable when it is needed most.

How Crises Control Supports the Manufacturing Industry

Crises Control provides a mass notification and incident response platform specifically designed for manufacturing:

- Integrated Alerts: Notify staff, contractors, and visitors across multiple channels quickly.

- QR Code Registration: Track everyone on site and include them in notifications immediately.

- Task Management: Assign responsibilities, track completion, and escalate tasks automatically.

- Public Alerting: Send notifications to local areas affected by larger incidents, protecting privacy while keeping people informed.

- Data-Driven Insights: Review reports after incidents to improve communication and response strategies.

By combining these features, Crises Control helps manufacturers prevent communication breakdowns, respond faster, reduce downtime, and maintain safety and compliance.

Taking Action to Prevent Communication Failures

Communication breakdowns in manufacturing plants can have serious consequences for safety, operations, and finances. Mass notification software provides a reliable system to send urgent messages, coordinate teams, and maintain oversight during any incident.

Crises Control enables manufacturers to act quickly, keep staff safe, and maintain operational continuity.

Book a free demo today to see how Crises Control can transform communication in your manufacturing plant.

Request a FREE Demo