Written by Anneri Fourie | Crises Control Executive

Automotive manufacturing involves tightly coordinated production, high-speed machinery, and the handling of hazardous materials. A single incident can disrupt worker safety, production flow, and supply chains across multiple sites. When communication is slow or unclear, small issues escalate into costly disruptions.

Mass Notification Software offers a solution by delivering real-time alerts, coordinating responses, and confirming employee safety across factory floors, offices, and global sites. For automotive manufacturers, this technology ensures that teams act quickly, know what to do, and have the information they need to keep operations running safely.

This article highlights five critical incident scenarios automotive manufacturers should prepare for, common pitfalls that prolong disruptions, and how a structured, technology-driven communication strategy reduces risk.

Why Mass Notification Software Is Central to Emergency Response Strategy

An emergency response plan provides structured steps to protect staff, limit damage, and maintain essential operations. These plans include defined responsibilities, communication pathways, activation triggers, and clear workflows for each type of incident.

Mass Notification Software ensures that these plans work in practice. Alerts can reach all relevant employees instantly via mobile, SMS, email, voice calls, and desktop notifications. Supervisors, maintenance teams, and emergency responders receive the information they need without delay.

Manufacturers with multiple plants or international operations benefit from a Mass Notification Platform for Global Teams. Cloud-based systems support real-time updates, automated escalation, task-driven workflows, and communication routes optimised for noisy, dynamic factory environments.

Integrated communication ensures that production lines, chemical handling areas, cyber operations, and supply chains remain coordinated, reducing the risk of miscommunication or slow reactions.

Incident Scenario 1: Production Line Machinery Failure

Core equipment failures can cause extensive downtime, affect delivery schedules, labour allocation, and stock availability, and sometimes lead to injuries.

An effective emergency response plan for machinery failure includes:

- Clear steps for isolating faulty equipment

- Immediate notifications to maintenance teams, shift leaders, and safety officers

- Pre-defined escalation routes for prolonged disruptions

- Access to site plans, repair instructions, and risk assessments

- Communication channels for updating production control teams and logistics

Industry-wide semiconductor shortages have forced major manufacturers to stop production for weeks, demonstrating how fragile production is when alternative communication routes are not in place.

A Mass Notification System for Manufacturing helps by sending alerts to large groups instantly, recording confirmations, and enabling two-way updates. Cloud-based mass notification software for multi-site manufacturers improves visibility and coordination, allowing teams across different plants to act in unison.

Incident Scenario 2: Chemical Spills and Hazardous Material Incidents

Chemical spills are common in automotive plants, from painting lines and adhesives to battery materials and coolants. Delays in communication can turn a minor spill into hours of lost production.

A strong response plan includes:

- Immediate safety instructions for employees in affected zones

- Activation of evacuation or shelter-in-place procedures

- Notifications to trained hazardous material response teams

- Access to safety data sheets and decontamination steps

- Alerts to external responders if required

A paint line chemical spill that takes twenty minutes to communicate can result in more than four hours of production stoppage. Facilities that implement multi-channel alert systems report evacuation times dropping from over eight minutes to under three minutes.

Mass notification systems for automotive manufacturing plants strengthen compliance and safety by delivering precise instructions rapidly. Automated escalation ensures that if someone cannot acknowledge an alert, the message is sent to a designated alternative, maintaining operational clarity and safety.

Incident Scenario 3: Fire and Facility Evacuation

Automotive facilities contain flammable materials, high-voltage equipment, and moving machinery. Fires can escalate quickly, making rapid evacuation and clear communication essential.

A fire response plan should include:

- Step-by-step evacuation routes

- Roll calls to confirm employee safety

- Notifications for supervisors, floor managers, and emergency wardens

- Pre-configured templates for different levels of evacuation

- Integration with access control and muster points

Employee Mass Notification Systems allow supervisors to see in real time who has responded, who is safe, and who may still be in danger. Manufacturers that conduct regular Business Continuity Planning (BCP) drills improve staff familiarity with evacuation instructions and strengthen response discipline. Drills confirm that responsibilities are clear, reveal gaps in plans, and help teams act confidently.

Incident Scenario 4: Cybersecurity Disruption and Operational Technology Outages

Digital systems now control many aspects of automotive manufacturing, from robotics to supply chain platforms. Cyberattacks or system failures can disrupt production, compromise data, or affect intellectual property.

An effective cyber incident plan includes:

- Defined triggers for activation

- Communication pathways for IT, plant management, and operations

- Steps to switch to manual processes where feasible

- Prioritisation of critical systems

- Coordination across sites that share IT infrastructure

Employees need guidance during disruptions, including how to log incidents, follow temporary processes, and maintain safe operations. Mass Notification Software supplies real-time instructions and replaces informal communication that may be unreliable during cyber events. Manufacturers using integrated notification systems typically report reducing incident response time by sixty to seventy percent compared to manual methods.

Incident Scenario 5: Supply Chain Breakdown Affecting Production Continuity

Automotive production depends on a stable supply chain. Disruptions from transport delays, supplier failures, geopolitical events, extreme weather, or shortages of critical parts can create immediate risks to delivery and revenue.

A supply chain response plan should include:

- Rapid alerts to procurement, production planning, and logistics teams

- Notifications to customer service for managing expectations

- Activation of alternative suppliers or redistribution of stock

- Clear communication routes for internal and external stakeholders

Using a Mass Notification Platform for Global Teams helps synchronise communication across regions. Multi-site visibility allows planners to adjust schedules, redistribute stock, and maintain continuity with minimal delay. Notifications extend beyond internal teams to include external partners, carriers, and customers, reducing operational impact.

How Crises Control Supports Automotive Manufacturers

Crises Control provides technology designed to make emergency response faster, clearer, and more coordinated. Key benefits include:

- Multi-channel alerts that reach maintenance teams in noisy factory environments and office staff simultaneously, ensuring no one misses critical safety information

- Real-time status updates that allow supervisors to confirm employee safety and track response progress across multiple sites

- Automated escalation paths tailored to factory workflows, reducing delays when a recipient cannot acknowledge an alert

- Incident management tools that assign tasks, track progress, and maintain compliance, helping teams act decisively and document every step

- Cloud-based infrastructure supporting global operations, ensuring notifications and updates remain reliable even during local IT issues

Manufacturers using Crises Control typically report faster, more organised responses, improved safety outcomes, and reduced production downtime. The system allows teams to focus on solving the incident rather than chasing information.

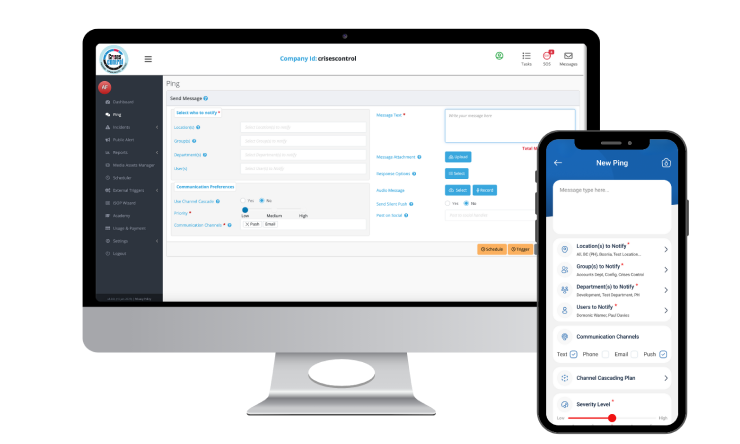

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Strengthen Your Emergency Preparedness with Crises Control

Automotive manufacturers face diverse challenges that can disrupt production, threaten worker safety, and damage reputation. A modern communication system ensures teams respond quickly, coordinate effectively, and maintain operational continuity.

If you want to improve the speed and accuracy of your emergency communication, contact our team for a free demo and see how Crises Control can strengthen your response capability across all your facilities.

Request a FREE Demo