Written by Anneri Fourie | Crises Control Executive

Food and beverage manufacturing depends on smooth, uninterrupted production. A single incident on a production line can create delays, compromise food safety, or even damage a brand’s reputation. For example, imagine a cyber-attack shutting down a packaging line, leaving batches of products unprocessed, while employees scramble to figure out what to do next. Without clear guidance, mistakes can escalate costs, regulatory penalties, and safety risks.

Mass notification software offers a solution. It ensures that alerts reach the right people immediately, workflows are coordinated automatically, and every action is documented. This allows teams to respond quickly and effectively, reducing the impact of incidents and maintaining production integrity.

This blog examines common operational risks in food manufacturing, the role of real-time alerts, and how cloud-based solutions improve crisis management across multiple sites.

Understanding Operational Risks on Production Lines

Food production is highly complex. Lines rely on integrated systems such as ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and SCADA (Supervisory Control and Data Acquisition). If these systems fail, production slows or stops, inventory records become unreliable, and compliance reporting is disrupted.

Common risks include:

- Cyber-attacks on production systems: Ransomware or system breaches can stop lines instantly and threaten food safety.

- Equipment failures: Malfunctioning machinery can spoil batches and delay deliveries.

- Human error: Miscommunication during incidents can lead to mistakes on the floor.

- Regulatory risks: Delays in addressing issues can violate food safety standards and data protection laws.

Traditional methods like phone trees or email notifications are too slow to coordinate responses during incidents. Staff may receive conflicting instructions, or alerts may be delayed entirely. These gaps increase the risk of downtime, wasted products, and compliance breaches.

Incident management software combined with mass notification software solves these problems by providing structured, automated communication and workflows.

How Mass Notification Software Improves Crisis Response

Mass notification software delivers alerts across multiple channels such as SMS, email, phone calls, mobile apps, and Microsoft Teams. This ensures that employees on the production floor, supervisors, and central operations teams all receive the same instructions in real-time.

Key benefits include:

- Faster engagement: Pre-configured alerts reach the right people without delay.

- Multi-site coordination: Alerts can be customised for each production facility, ensuring relevant guidance for local teams.

- Reduced human error: Automation prevents alerts from being missed or miscommunicated.

- Audit-ready records: Every alert and action is logged, supporting regulatory compliance.

For food manufacturers, these features help maintain operational resilience and meet regulatory obligations from local food safety authorities to international cyber security frameworks.

Crises Control provides a platform that centralises all alerts and workflows, allowing teams to respond quickly while keeping accurate records for compliance purposes.

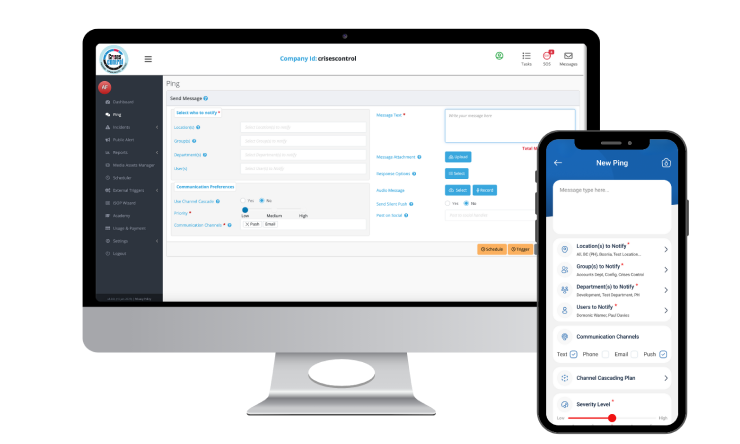

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Real-Time Incident Alerts for Employees

The time it takes for staff to receive information during an incident can determine the scale of the problem. Real-time incident alerts for employees give teams the guidance they need to act immediately. For example:

- If a batch shows contamination risk, the production line can be paused instantly.

- If a system is compromised, IT staff receive clear steps to isolate the threat.

- If an evacuation is needed, employees receive instructions without confusion.

Without real-time alerts, staff may continue production unaware of the risk. This can lead to product spoilage, safety hazards, and regulatory violations.

Crises Control integrates automated workflows with notifications. Tasks are assigned to the right roles, ensuring maintenance teams, quality control, and management know exactly what to do. This coordination reduces downtime, minimises errors, and maintains safety across the production line.

Incident Management Software for Structured Responses

Effective incident management requires more than sending alerts. It requires structured workflows that guide teams through each step.

Features of incident management software include:

- Defined workflows for different types of incidents, from equipment failures to cyber breaches.

- Escalation rules that automatically involve higher-level management if tasks are not completed.

- Centralised dashboards that show the status of multiple sites simultaneously.

- Automated logging to maintain records for audits and regulatory reporting.

Structured incident management ensures the correct actions are taken without confusion. It also helps demonstrate due diligence to regulators such as the FDA in the US, the UK Food Safety Act authorities, and the EU General Food Law.

With Crises Control, manufacturers can integrate these workflows with notifications, ensuring that alerts and task assignments work together to solve problems efficiently.

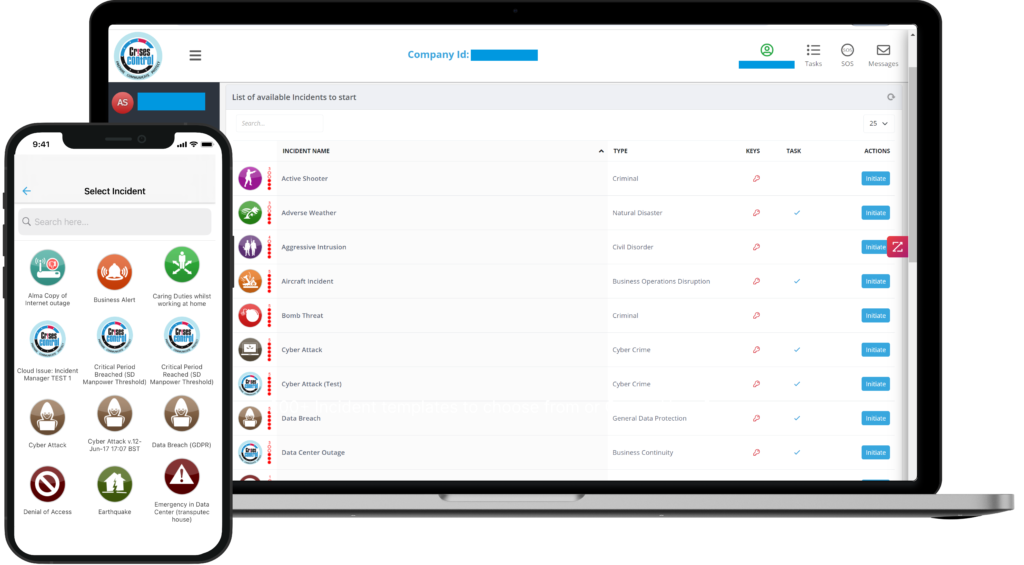

Interested in our Incident Management Software?

Customise your Crisis Incident Management Software to meet your specific needs with our flexible tools & stay connected and informed during the crisis and incident management process

Cloud-Based Crisis Management Across Multiple Sites

Manufacturers with multiple production facilities face the challenge of maintaining consistency. Cloud-based solutions allow centralised management while adapting to the needs of individual sites.

Cloud-based crisis management provides:

- High availability alerts that continue even if local IT systems fail.

- Centralised control across all production sites.

- Secure storage for incident records and audit trails.

- Rapid scalability for temporary sites or expansion.

Cloud solutions ensure that all teams operate under the same protocols, while local conditions are accounted for in alerts. Managers can monitor every production line in real-time, coordinating response across sites without confusion.

Supporting Compliance and Audit Readiness

Food manufacturing is heavily regulated. Maintaining records and demonstrating effective responses is critical. Mass notification and incident management software supports compliance by:

- Logging all alerts and actions for audit purposes.

- Providing GDPR-compliant notifications when employee data is involved.

- Supporting DORA-aligned workflows for operational resilience in the EU.

- Automating escalation and traceability to meet regulatory requirements.

These tools help manufacturers demonstrate responsible practices during inspections and reduce the risk of penalties.

Improving Day-to-Day Efficiency with Alerts

Mass notification software is not only for emergencies. It can improve everyday operations:

- Streamlining communication reduces unnecessary downtime.

- Role-based task assignments improve accountability.

- Integration with production systems allows context-aware alerts.

- Analytics highlight bottlenecks and weak points in workflows.

These benefits help manufacturers improve production reliability and safety standards, even outside of crisis situations.

Summary

Food and beverage manufacturing faces multiple risks, from cyber threats to equipment failures. Mass notification software with integrated incident management capabilities and real-time alerts for employees allows teams to respond quickly, protect safety, maintain compliance, and keep production lines running efficiently.

Crises Control provides a cloud-based platform designed for food manufacturing, giving teams the tools to coordinate across sites, automate workflows, and maintain operational resilience.

To see how Crises Control can help your production lines stay safe and efficient, contact us today to get a free personalised demo.

Request a FREE Demo