Written by Anneri Fourie | Crises Control Executive

Food and beverage manufacturing faces a unique set of challenges. Production schedules are tight, regulatory requirements are strict, and incidents in one part of a plant can ripple across operations and multiple sites. Cyber-attacks, food contamination, IT system outages, or supply chain disruptions can quickly escalate if communication and response are not coordinated.

Business continuity software plays a critical role in these environments. It helps manufacturers maintain safe production, protect brand trust, and meet compliance obligations while incidents are unfolding. This article examines how food manufacturers maintain production during disruptions, how mass notification software contributes to operational resilience, and how Crises Control supports these processes in complex manufacturing setups.

Why Business Continuity is Different in Food Manufacturing

Food manufacturing combines physical, digital, and regulatory risk. One disruption can simultaneously affect people, products, systems, and compliance.

Some common incidents include:

- Cyber-attacks that impact ERP, MES, or SCADA systems

- Food contamination or allergen exposure requiring immediate batch isolation

- Power or utility failures affecting temperature-controlled processes

- Loss of visibility across multiple plants or distribution centres

- Breakdowns in communication between operations, quality, IT, and leadership

Traditional call trees or static continuity plans are not enough. Teams need structured workflows, real-time communication, and clear accountability supported by technology built for fast decision-making.

How Business Continuity Software Supports Food Manufacturing

Business continuity software provides a structured approach to managing disruption from the first alert to recovery and review. For food manufacturers, it turns complex plans into practical, actionable steps.

Key features include:

- Centralised access to continuity and incident response plans

- Role-based task assignment across operations, quality, IT, and leadership

- Real-time visibility of incidents across multiple sites

- Automated logging for audits and regulatory reporting

Unlike paper-based or static plans, digital continuity platforms allow manufacturers to adapt in real time, removing reliance on memory or manual coordination. This ensures decisions are consistent and documented.

Operational Resilience in Food Manufacturing

Operational resilience means absorbing disruption while maintaining control of core operations. In food manufacturing, resilience involves continuing safe production where possible and executing controlled shutdowns or recalls when necessary.

Business continuity software strengthens resilience by:

- Standardising responses across sites while allowing local adjustments

- Delivering accurate information to decision-makers at the right time

- Reducing reliance on informal communication channels

- Enabling repeatable responses that meet regulatory standards

Resilience is built before incidents occur. Digital platforms let manufacturers test scenarios, refine response plans, and train teams through simulations, uncovering weaknesses before they become failures.

The Role of Mass Notification Software in Maintaining Production

Reliable communication is essential during any incident. Food manufacturing teams are spread across production floors, control rooms, offices, and remote locations. Mass notification software ensures the right people receive instructions quickly.

Use cases include:

- Alerting production teams to stop or isolate a line

- Notifying quality and food safety teams of potential contamination

- Escalating IT incidents affecting production systems

- Coordinating leadership response during major events

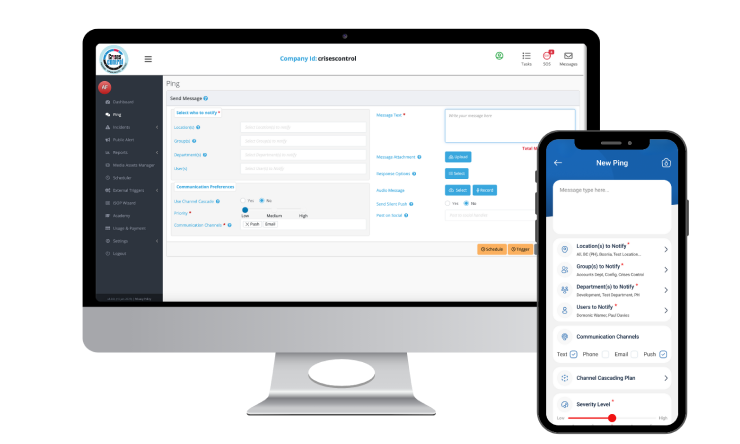

Crises Control’s Ping mass notification tool sends alerts through mobile app, SMS, voice, email, desktop, and Microsoft Teams. Using multiple channels reduces the chance of missed messages during noisy or chaotic conditions on the factory floor.

Integrating Business Continuity and Mass Notification

Continuity planning and alerting are often treated as separate functions. Integration enhances effectiveness.

When combined, business continuity and mass notification software provide:

- Automatic alerts triggered by incident activation

- Clear instructions aligned to approved response plans

- Confirmation of message receipt and staff availability

- Escalation rules when responses are delayed

This integration reduces reliance on manual coordination during critical moments and supports faster, controlled decision-making.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

How Food Manufacturers Maintain Production During Disruptions

Maintaining production is not always about keeping lines running at full capacity. It is about making informed decisions that protect safety, compliance, and long-term output.

Manufacturers using digital continuity platforms follow a structured approach:

Early Detection and Alerting

Incidents are identified quickly, whether from IT monitoring, quality systems, or frontline staff. Early alerts reduce escalation risk.

Example scenario: A temperature sensor in cold storage flags a deviation overnight. The system immediately alerts operations and quality teams to investigate before products are compromised.

Immediate Coordination

Relevant teams receive instructions via mass notification software, with roles and priorities clearly defined. Staff know exactly what action to take without delay or confusion.

Controlled Response

Incident workflows guide teams through isolation, investigation, communication, and recovery steps. This reduces guesswork and ensures safe, compliant outcomes.

Example scenario: During a contamination alert, pre-defined workflows trigger batch isolation, staff notification, regulatory reporting, and quality inspection steps automatically.

Executive Oversight

Leadership sees real-time updates across all affected sites. This allows consistent decision-making and timely communication with regulators or partners.

Post-Incident Review

Automated logs and audit trails provide evidence for regulatory review and support continuous improvement. Lessons learned inform updates to incident plans and training exercises.

This structured approach limits downtime, reduces waste, and preserves customer trust.

Supporting Compliance with Business Continuity Software

Regulatory compliance is a constant requirement. Manufacturers must show incidents are managed consistently, transparently, and legally.

Business continuity software supports compliance by:

- Maintaining time-stamped incident logs

- Recording decisions, actions, and communications

- Supporting audit-ready reporting

- Demonstrating preparedness through testing and exercises

Crises Control is designed for global operations, supporting UK, EU, Middle East, North America, and beyond. Secure cloud hosting, data governance controls, and role-based access meet regulatory expectations without complicating operations.

Managing Multi-Site Operations with Confidence

Multi-site manufacturers face increased risk when responses are inconsistent. Fragmented tools can slow coordination and lead to mistakes.

Crises Control enables centralised incident management with site-specific control:

- Activate incidents globally or locally

- Tailor notifications by location and role

- Maintain consistent response standards

- Share situational awareness across all sites

This approach ensures continuity and reduces fragmentation during critical events.

Cyber Resilience and IT Outages

Digital systems support nearly every stage of food production. ERP, MES, and automation platforms are crucial for scheduling, traceability, and compliance.

When these systems fail, the impact is immediate. Business continuity software helps by:

- Coordinating IT and operational teams

- Triggering predefined response plans

- Communicating system status to affected staff

- Supporting safe workarounds during outages

Crises Control integrates incident management and communication so technical failures do not escalate into operational crises.

Testing Preparedness Before Real Incidents

Many gaps are only discovered during live incidents. Testing before disruption is critical.

Crises Control allows manufacturers to:

- Run simulation incidents

- Conduct tabletop exercises

- Test notification reach and response times

- Validate continuity plans across sites

These exercises improve confidence and reveal practical adjustments that strengthen resilience long before a disruption occurs.

What Makes Crises Control Different for Food Manufacturers

Crises Control is designed for high-risk, regulated, time-sensitive environments. It supports food manufacturers with:

- Digital continuity and incident plans

- Integrated mass notification and escalation

- Secure, high-availability cloud infrastructure

- Mobile access for frontline teams

- Detailed reporting and audit trails

The platform provides structure, clarity, and reliable communication while allowing experienced staff to make informed decisions.

Moving from Reactive Response to Controlled Continuity

Disruptions are unavoidable. The difference lies in response. Manufacturers using manual processes or fragmented tools face higher risk, longer downtime, and compliance exposure. Those using business continuity software with integrated mass notification can:

- Strengthen operational resilience

- Maintain control during incidents

- Demonstrate preparedness to regulators and stakeholders

Speak to Crises Control

To see how Crises Control can support business continuity and mass notification in your food manufacturing operations, speak to our team.

Request a FREE Demo