Written by Anneri Fourie | Crises Control Executive

Defence and space manufacturing involves complex, high-risk operations. Facilities handle flammable materials, high-precision machinery, and sensitive technologies across multiple secure sites. In this environment, even small incidents can disrupt production, put staff at risk, and create regulatory exposure.

Relying on paper-based plans or manual procedures leaves organisations vulnerable. During an incident, critical documents may be inaccessible, communication can fail in noisy or restricted areas, and response tasks may be unclear. Staff may know their roles in theory but struggle to coordinate in practice.

Business continuity software provides a digital solution to these challenges. It ensures operations continue during both planned and unplanned events, assigns tasks clearly, enables real-time oversight, and produces records suitable for audits.

What Is Business Continuity Software?

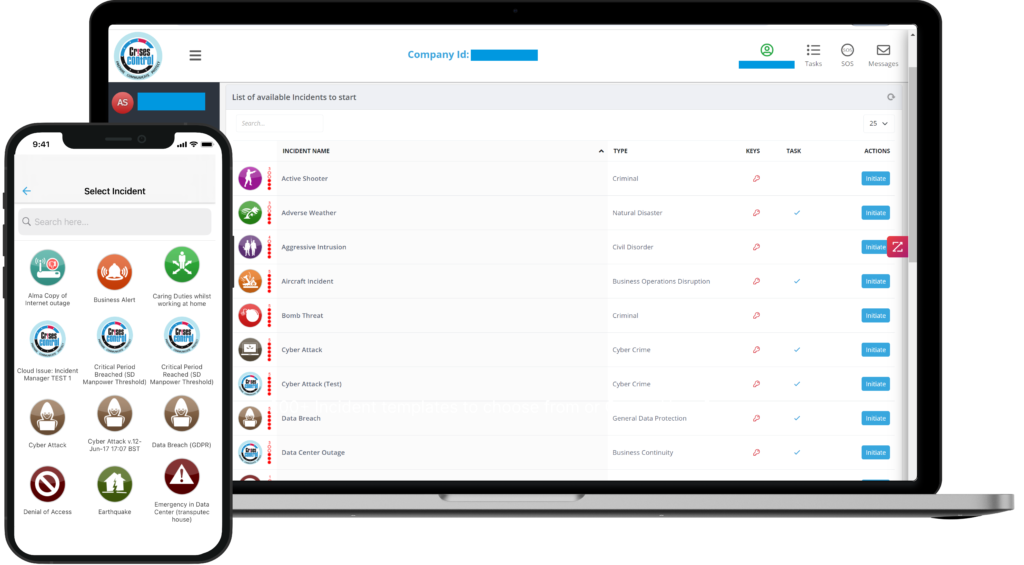

Business continuity software is a platform that allows organisations to plan, manage, and monitor operational continuity. It brings together crisis planning, task coordination, communication, and compliance tracking in a single system.

Key features include:

- Digital continuity and crisis plans: All procedures are centralised and actionable.

- Role-based task assignment: Tasks are allocated by responsibility, not by individual, reducing confusion.

- Secure, multi-channel communication: Alerts and instructions reach the right people quickly, even in noisy or restricted zones.

- Audit-ready reporting: Every action is timestamped and logged for regulatory compliance or internal review.

In practice, this means that teams can respond confidently and efficiently, whether managing a minor equipment failure or a multi-site production disruption.

Why Defence and Space Manufacturing Faces Unique Challenges

Business continuity in this sector is not simply about keeping machines running. The operational environment presents challenges that make manual continuity planning risky.

1. High-risk production environments

Manufacturing plants handle combustible materials, high temperatures, and sensitive equipment. A small fire, chemical leak, or machinery failure can have cascading effects. Paper-based plans may be inaccessible, and relying on memory or verbal instructions can delay critical action.

Example scenario: A small fire in a restricted assembly hall was contained within 12 minutes using a structured, digital workflow, while production resumed on unaffected lines. Without a centralised system, response would have been slower, increasing risk to staff and equipment.

2. Multi-site and secure operations

Defence and aerospace companies often operate across multiple secure locations, sometimes internationally. Communication between sites is not straightforward, and procedures must comply with local regulations.

Without centralised visibility and local execution authority, teams risk duplicating efforts or missing essential tasks. Digital continuity platforms allow site-level teams to act within predefined workflows while giving management a complete operational picture across all locations.

3. Regulatory and contractual obligations

Regulators and clients expect organisations to demonstrate operational readiness. Manual logs are often incomplete, undated, or inconsistent. Failure to provide proof of response can lead to regulatory fines, contract penalties, or reputational damage.

Digital continuity software creates records that are automatically timestamped, secure, and audit-ready, reducing the administrative burden while providing confidence that obligations are met.

Common Misconceptions That Put Continuity at Risk

Many defence and aerospace organisations hold assumptions that make continuity planning less effective.

Static plans are sufficient

Some teams assume that having a plan on paper proves preparedness. In practice, plans that cannot be accessed or executed during high-pressure situations are ineffective. Teams often struggle to follow complex, multi-step procedures in real time without guidance.

Alerts alone solve the problem

Sending multiple alerts does not guarantee an effective response. Without task context, staff may become overwhelmed or unsure which action to prioritise.

Compliance is about intention, not evidence

Regulators expect proof of action, not just plans. Handwritten or manually compiled logs often fail to demonstrate that tasks were completed correctly or on time.

Business continuity software addresses these gaps by centralising plans, assigning tasks clearly, and automatically recording actions.

How Business Continuity Software Supports Real Operations

Digital continuity platforms offer practical advantages that directly improve response and resilience.

Structured task assignment and live updates

Tasks are assigned by role and tracked in real time. Supervisors can see which actions are completed and which require attention, giving a clear operational picture.

Example scenario: During an equipment failure affecting two production lines, live task tracking allowed teams to redistribute personnel efficiently, restoring full operations within 30 minutes.

Coordinated multi-site execution

A centralised dashboard provides oversight across all locations, while site teams retain local authority to act within defined procedures. This reduces duplication and ensures consistent, coordinated response across secure zones.

Secure, multi-channel communication

Alerts include actionable instructions rather than just notifications. Employees can acknowledge tasks, escalate delayed responses, and remain informed even in noisy or restricted areas. This integration reduces confusion and improves speed of execution.

Audit-ready reporting

Every action, notification, and update is automatically logged and timestamped. This allows organisations to meet regulatory requirements and provide evidence to clients or auditors without additional effort during or after an incident.

Maintaining Continuity During Planned and Unplanned Events

Business continuity software is effective for both predictable and unexpected events.

- Planned events: Scheduled maintenance, drills, or workforce changes can be managed with minimal disruption. Workflows ensure all teams know their roles and responsibilities.

- Unplanned events: Fires, equipment breakdowns, or security breaches are handled through structured task lists and real-time oversight. Staff follow clear steps, while management monitors progress across all sites.

By combining digital planning with real-time execution, downtime is minimised, risk is reduced, and employees can act safely and confidently.

Integrating Continuity with Incident and Crisis Management

Business continuity is most effective when connected with broader operational systems.

- Incident Management Software: Detects issues quickly, assigns tasks, and tracks progress.

- Mass Notification Software: Ensures critical alerts reach the right personnel instantly.

- Cloud-based access: Maintains continuity even during IT failures or cross-site disruptions.

Integration creates a single source of truth, linking planning, execution, and post-event review. This enables continuous improvement and operational resilience over time.

Interested in our Incident Management Software?

Flexible Incident Management Software to keep you connected and in control.

Practical Guidance for Defence and Aerospace Teams

When evaluating business continuity software, consider these questions:

- Does it provide role-based workflows for clear ownership?

- Can progress be tracked in real time across multiple sites?

- Are reports automatically generated and audit-ready?

- Are communications secure across all channels, even in restricted zones?

- Does it integrate with incident management and mass notification tools?

Answering these ensures the software supports operational needs and not just compliance checklists.

Challenging Common Assumptions

Many organisations assume that drills prove readiness. In practice, drills alone rarely replicate real-world conditions:

- Infrequent or inconsistent drills fail to test decision-making under pressure.

- Paper-based or siloed digital plans are inaccessible during actual incidents.

- Teams may know individual roles but lack visibility of interdependencies.

Business continuity software bridges these gaps, providing centralised, actionable plans and live oversight for realistic preparedness.

Crises Control in Practice

Crises Control illustrates how continuity software works in defence and aerospace:

- Digitalisation of plans ensures procedures are actionable and centralised.

- Role-based task assignment provides accountability and clarity.

- Secure cloud access allows teams to respond from any site.

- Audit-ready reporting gives verifiable proof of compliance to regulators and clients.

This approach enables organisations to continue operations, reduce risk, and maintain compliance with confidence.

Take the Next Step

If your organisation is reviewing continuity capabilities or preparing for future operational and regulatory demands, speak to the Crises Control team.

Request a FREE Demo