Written by Anneri Fourie | Crises Control Executive

Aerospace and defence manufacturing is unforgiving when things go wrong. Production environments involve hazardous materials, specialist machinery, tightly controlled access, and people working under strict safety and security rules. When an incident happens, whether it is a fire, equipment failure, security breach, or sudden loss of critical systems, organisations do not have the luxury of working things out as they go.

The problem many organisations face is not a lack of planning. Most have procedures, response documents, and compliance frameworks in place. The real issue appears when those plans have to be used under pressure. Information is scattered, communication is slow or unclear, and people are unsure who is responsible for what. This gap between planning and action is where risk increases.

Crisis management software for aerospace manufacturing exists to close that gap. It provides a structured way to communicate, coordinate, and document response activities while an incident is unfolding, not afterwards. This article explains why crisis management is particularly difficult in aerospace and defence manufacturing, where traditional approaches fall short, and how digital platforms support safer and more controlled outcomes.

What crisis management software means in aerospace manufacturing

Crisis management software is a digital system that helps organisations prepare for, respond to, and recover from disruptive incidents using clear workflows, reliable communication, and recorded actions.

In aerospace and defence manufacturing, this typically includes:

- Secure emergency alerts sent to employees and contractors

- Role-based response tasks for safety, operations, engineering, and leadership teams

- A single view of incidents across sites and regions

- Automatic records of alerts, decisions, and actions taken during drills and real events

This is not about replacing safety culture or experience. It is about supporting people when stress, time pressure, and uncertainty make manual coordination difficult.

Why crisis management is uniquely challenging in aerospace and defence manufacturing

The risks faced by aerospace manufacturers are well understood. The difficulty lies in managing those risks when several pressures collide at once.

High-risk production environments

Facilities often deal with flammable substances, high temperatures, pressurised systems, and precision manufacturing equipment. Fire, explosion, or toxic exposure risks are real and can escalate quickly. Response measures must work in loud, restricted, and segmented areas of a site where visibility and movement may already be limited.

Secure zones and access restrictions

Many defence and space production sites operate under strict access controls. Personal devices may be restricted, and public address systems may not reach every area. This creates blind spots during emergencies where people may not receive instructions at the same time or in the same way.

Multi-site and cross-border operations

Large organisations often run multiple facilities across regions and countries. A local incident might require immediate site-level action while senior teams elsewhere need visibility to manage wider operational or regulatory impact.

Regulatory and contractual pressure

Defence authorities, aviation regulators, and customers expect evidence of preparedness and controlled response. During audits or investigations, organisations must show how alerts were issued, who responded, and whether approved procedures were followed.

Where traditional crisis management approaches struggle

Despite the complexity of the environment, many organisations still rely on tools and processes that were designed for simpler situations.

Paper-based and static plans

Emergency and continuity plans are often stored as documents on shared drives or in physical folders. During an incident, finding the right version and interpreting it under pressure can be difficult. These plans also assume that key people are available and systems are working, which is often not the case.

Fragmented communication tools

Email, landlines, messaging apps, and public address systems are frequently used together without a single point of control. Messages get delayed, duplicated, or missed entirely. There is also no reliable way to confirm who received and understood critical instructions.

Manual coordination during incidents

Incident managers often rely on phone calls and spreadsheets to track actions. This approach places a heavy burden on individuals at the worst possible time. It increases the chance of missed steps, duplicated effort, or delayed decisions.

Overconfidence in drills

Many organisations run regular drills and assume this equals readiness. Drills are usually planned events with full staffing and working systems. Real incidents rarely follow that script. Staff may be absent, information incomplete, and systems unavailable.

The real-world consequences of weak crisis management

When crisis management fails in aerospace manufacturing, the effects are immediate and long-lasting.

- Delayed evacuation or shelter instructions increase the risk of injury

- Conflicting messages reduce trust and compliance

- Production downtime extends beyond the initial incident

- Audit findings lead to corrective actions or contract risk

- Senior leaders lose confidence in the organisation’s ability to respond

These outcomes are rarely caused by one mistake. They usually come from gaps between planning, communication, and execution.

How mass notification supports secure and time-critical communication

Clear communication is the first requirement during any incident. Mass notification software for defence manufacturing supports this by sending alerts through multiple approved channels at once.

Practical use in secure environments

Effective platforms deliver messages through authorised mobile applications, SMS, voice calls, email, and desktop alerts. Using several channels increases the chance that messages reach people working in restricted or noisy areas without relying on a single system.

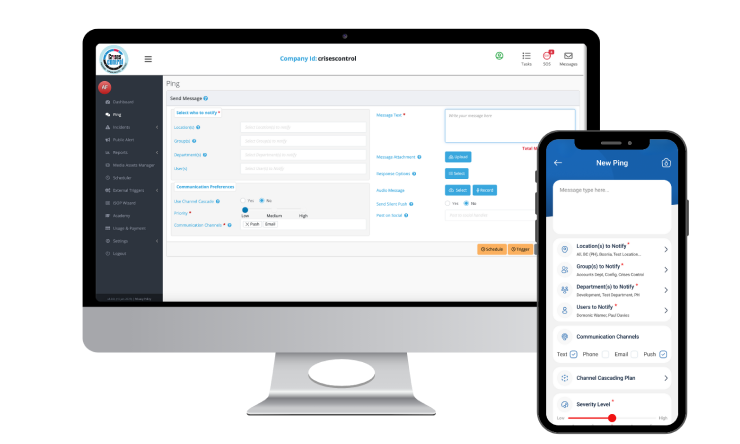

Example use case: Ping allows facility managers to notify all relevant personnel instantly while tracking acknowledgements in real time. This matters in aerospace operations where leaders need to know who has received instructions and who has not.

Acknowledgement and escalation

Sending a message is only part of the job. Organisations need to confirm receipt and understanding. Automated escalation ensures that non-responses are followed up without manual chasing, reducing delays and uncertainty.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Incident management beyond alerts

Alerts trigger action, but coordination determines outcomes. Incident management software for aerospace operations provides structure during complex situations.

Role-based response

Digital incident plans assign tasks based on roles rather than named individuals. This supports continuity when staff are unavailable or working across shifts. Each person sees only the actions relevant to their role, reducing confusion.

Real-time visibility

Incident leaders can see which actions are complete, which are pending, and where support is needed. This reduces reliance on verbal updates and allows better decision-making under pressure.

Built-in documentation

Actions and decisions are logged automatically as the incident unfolds. This supports learning, reporting, and accountability without adding extra work during the response.

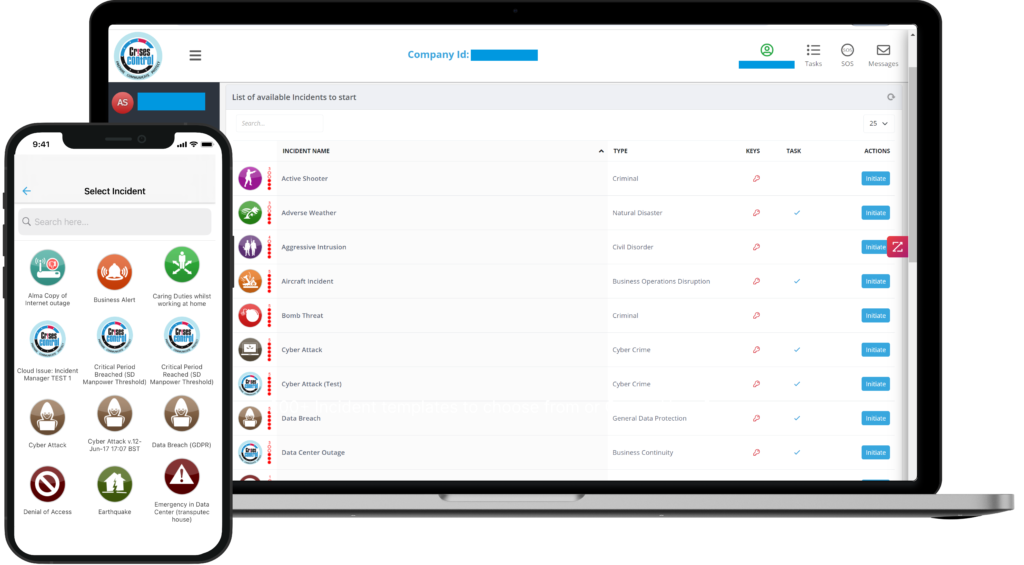

Interested in our Incident Management Software?

Flexible Incident Management Software to keep you connected and in control.

Supporting business continuity in aerospace and defence operations

Crisis response does not stop when the immediate danger has passed. Business continuity software for aerospace and defence supports recovery and stabilisation.

Linking response to recovery

Digital platforms connect emergency actions with continuity plans. This helps teams prioritise recovery steps, manage dependencies, and communicate progress to stakeholders.

Managing multiple locations

Central teams gain visibility across sites while local teams retain control of their response. This balance supports consistency without slowing down decision-making.

A common assumption that often fails

Many organisations believe that detailed plans and regular drills guarantee readiness. In reality, this assumption often breaks down.

Plans are written for ideal conditions. Drills are scheduled and observed. Real incidents involve missing staff, partial information, and competing priorities. Digital crisis management does not replace planning or training. It exposes weaknesses early by turning assumptions into actions that must work in real conditions.

Proving preparedness during audits and inspections

Auditors and regulators increasingly expect evidence rather than assurances. Proving emergency preparedness compliance in aerospace manufacturing audits depends on clear records of alerts, drills, and response actions.

Digital platforms support this by:

- Retaining records of exercises and real incidents

- Showing who was alerted and when

- Demonstrating alignment with approved procedures

- Supporting improvement based on real outcomes

This reduces audit friction and builds confidence with regulators and customers.

How Crises Control supports aerospace manufacturing organisations

Crises Control supports these needs by helping organisations digitalise crisis and continuity plans, coordinate role-based response, and communicate reliably during disruptions. Cloud-based access allows teams to reach plans and tools even when local systems are affected.

The platform is used during both exercises and real incidents, helping teams move from static documentation to coordinated action while keeping existing governance structures intact.

Building a more resilient crisis management capability

Improving crisis management in aerospace manufacturing is about reducing uncertainty and supporting people when pressure is highest.

Organisations that do this well focus on:

- Clear ownership of response roles

- Practical, actionable plans

- Reliable communication across environments

- Regular testing under realistic conditions

These principles apply regardless of organisation size or location.

Final thoughts

Crisis management in aerospace and defence manufacturing requires more than compliance-driven documentation. It requires systems and processes that work when conditions are difficult and information is incomplete.

For organisations reviewing their current approach, understanding how digital platforms support communication, coordination, and accountability is a practical step forward.

Request a FREE Demo