Written by Anneri Fourie | Crises Control Executive

Defence and space manufacturing facilities face a hard reality. When something goes wrong, there is rarely time to stop, gather people, and decide what to do next. Fires, chemical incidents, or security breaches demand immediate action, often in environments that are noisy, restricted, and tightly controlled.

The problem many organisations face is not a lack of procedures. It is the gap between what is written in an emergency plan and what actually happens when people are under pressure. Messages do not reach everyone. Instructions are unclear. Teams hesitate because they are unsure whether an alert applies to them.

An Emergency Mass Notification System for Defence Manufacturing addresses this gap by ensuring the right information reaches the right people quickly, even in complex and secure environments. It supports clear decision-making during incidents and helps organisations move from reactive responses to controlled, coordinated action.

This article explains why emergency response is particularly challenging in defence manufacturing, where common approaches fall short, and how structured, digital communication improves outcomes during real incidents.

What is an emergency response plan in safety-critical manufacturing environments?

An emergency response plan in safety-critical manufacturing environments is a practical framework that defines how incidents are identified, communicated, and managed to protect people, assets, and operations.

In defence and space manufacturing, this means having clear, tested actions for scenarios such as fires, evacuations, chemical spills, or security incidents. It also means ensuring those actions can be accessed and followed when normal working conditions break down.

In simple terms, a plan only works if people can understand it and use it during an incident.

Defence manufacturing emergency response plans must account for:

- Fire and explosion risks linked to flammable materials and high-energy processes

- Secure areas where access and movement are controlled

- Multiple shifts, contractors, and visiting personnel

- Regulatory and audit scrutiny

- Confidentiality during sensitive incidents

Plans that rely on paper documents, shared drives, or memory tend to fail when stress levels rise and time is limited.

Why emergency response is more complex in defence and space manufacturing

Emergency response in defence manufacturing is shaped by overlapping safety, security, and operational pressures. These factors often interact in ways that are difficult to predict.

High-risk production environments

Many defence facilities work with materials and processes that can escalate quickly if something goes wrong. Fires may spread faster due to fuel sources, while evacuation routes may be limited by machinery layout or secure zoning.

Secure and noisy working conditions

Sirens and verbal instructions are less effective in loud production areas or restricted zones. Workers may not hear alerts or may question whether they apply to their specific location.

Fragmented communication

Defence sites often involve permanent staff, contractors, and external responders. When communication methods differ between groups, delays and confusion become more likely.

Compliance without clarity

Meeting regulatory requirements does not always mean teams are ready to respond. Plans written for audits may lack the clarity needed for real-world decision-making.

Emergency response plan for manufacturing facilities: common weaknesses

Many defence manufacturers believe they are prepared because they have documented plans and run drills. Real incidents often reveal weaknesses that were not obvious beforehand.

Over-reliance on manual processes

Printed procedures, static PDFs, and email distribution lists assume people can find and interpret information while under pressure. During a fire or spill, this assumption rarely holds true.

Generic instructions

Evacuation messages that apply to everyone often help no one. Different roles and locations require different actions. When instructions lack detail, people hesitate.

No confirmation of alert delivery

Organisations often assume alerts are received. Without confirmation, decision-makers do not know who is safe, who is moving, or where problems remain.

Predictable drills

Drills that follow the same pattern each time build familiarity, not readiness. Real incidents introduce uncertainty, blocked routes, and competing priorities.

Key elements of an emergency response plan for fire and evacuation in defence facilities

Effective emergency response planning focuses on execution, not just documentation.

Clear triggers for action

Plans should define what events trigger alerts and escalation. This includes thresholds for evacuation, partial shutdown, or shelter-in-place instructions.

Role-based actions

Supervisors, fire marshals, security teams, and senior leaders all need different information. Role-based instructions reduce confusion and speed up response.

Secure mass communication

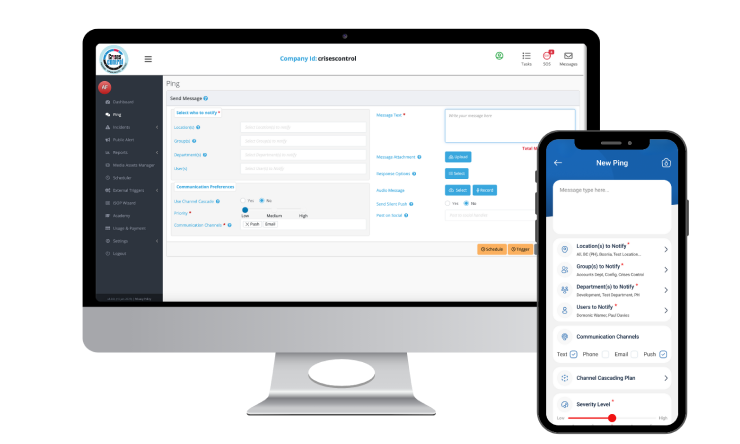

An Emergency Mass Notification System for Defence Manufacturing ensures messages reach people through channels they can access, including SMS, email, voice calls, app notifications and Microsoft Teams. This is critical in noisy or restricted environments.

Visibility and accountability

Knowing who has received and acknowledged instructions allows leaders to make informed decisions during the incident.

Integrated incident management

Communication works best when it is connected to incident tracking and task management. This supports control during the response and evidence after the event.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Fire response and evacuation scenarios in defence manufacturing

Scenario-based planning exposes how systems perform under pressure.

Scenario 1: Fire in a high-risk production area

A fire breaks out near specialist equipment handling flammable materials. Certain zones must evacuate while others remain operational for safety reasons.

Targeted alerts instruct affected teams to evacuate using specific routes. Supervisors receive prompts to confirm clearance. Leadership can see acknowledgements in real time, reducing uncertainty.

Scenario 2: Chemical spill requiring partial evacuation

A spill occurs in a confined area. Evacuating the entire site would increase risk and disruption.

Targeted notifications instruct nearby teams to evacuate while others shelter in place. Response teams receive clear, controlled instructions to prevent panic.

Scenario 3: Security breach during evacuation

An unauthorised access incident occurs at the same time as a fire alarm. Movement through certain zones is restricted.

Integrated incident management software for fire and evacuation response allows safety and security teams to coordinate actions without issuing conflicting instructions.

Crisis management vs emergency response in defence manufacturing incidents

A common mistake is treating crisis management and emergency response as the same activity.

Emergency response focuses on immediate actions such as evacuation, containment, and safety communication. Crisis management focuses on oversight, regulatory reporting, and longer-term recovery.

In defence manufacturing, both must run side by side. Frontline teams need clear, practical instructions. Leadership needs situational awareness and control.

Digital platforms support this separation by providing structured actions for responders while giving leaders a clear picture of what is happening.

Challenging a common assumption: drills alone mean preparedness

Many organisations assume regular drills equal readiness. This assumption often breaks down during real incidents.

Drills tend to follow known patterns. People know where to go and what to expect. Real incidents rarely follow the same script.

Unexpected factors such as blocked exits, equipment failures, or delayed alerts expose weaknesses that drills did not reveal.

Simulation-based incident testing introduces variation and uncertainty in a controlled way. This helps teams practise decision-making, not just movement.

Practical constraints organisations often face

Defence manufacturers often work within tight constraints:

- Long approval cycles for new systems

- Legacy infrastructure

- Security and data handling requirements

- Budget planning tied to multi-year programmes

Effective emergency communication platforms work within these limits. They complement existing processes rather than replacing them overnight.

Compliance, accountability, and audit readiness

Regulators expect evidence that organisations can respond effectively to emergencies.

An Emergency Mass Notification System for Defence Manufacturing supports this by providing:

- Records of alerts and acknowledgements

- Evidence of drills and simulations

- Incident timelines and response actions

- Secure handling of sensitive data

Crises Control supports these needs by digitalising crisis and continuity plans and enabling structured, role-based response without adding unnecessary complexity.

Human factors in emergency response

People do not respond to emergencies as they do to routine tasks. Stress, fatigue, and uncertainty affect decision-making.

Clear instructions, familiar tools, and consistent processes reduce hesitation. Systems that support people rather than overwhelm them improve safety and control during incidents.

Preparing for incidents that test assumptions

Real incidents rarely happen under ideal conditions. Power outages, network disruptions, and access restrictions are common.

Cloud-based platforms with mobile access help maintain communication when other systems fail. Planning for degraded conditions is part of realistic preparedness.

Building a response capability that holds up under pressure

Effective emergency response in defence manufacturing goes beyond compliance. It requires systems that support people during complex, fast-moving incidents.

An Emergency Mass Notification System for Defence Manufacturing plays a central role by enabling clear communication and structured execution.

Crises Control provides a practical example of how organisations can move from static plans to actionable, role-based response supported by secure, cloud-based access.

Next steps for defence manufacturing leaders

Emergency preparedness should be reviewed through the lens of real incidents, not audits alone. Leaders should consider whether current approaches would work during a complex, evolving situation.

To explore how digitalised plans and reliable emergency communication can strengthen preparedness, speak with the Crises Control team.

Request a FREE Demo

FAQs

1. What is an emergency response plan in safety-critical manufacturing environments?

It is a structured approach that defines how incidents are identified, communicated, and managed to protect people and operations during high-risk events.

2. Why is mass notification critical in defence manufacturing?

It ensures instructions reach staff quickly across secure, noisy, or multi-site environments where traditional alarms may not be effective.

3. How does incident management software support fire and evacuation response?

It links communication, task coordination, and documentation, giving teams visibility and control during incidents.

4. What is the difference between crisis management and emergency response?

Emergency response focuses on immediate safety actions, while crisis management addresses oversight, compliance, and recovery.

5. How can organisations prove emergency preparedness to regulators?

By maintaining clear records of alerts, drills, incidents, and response actions that demonstrate readiness and accountability.