Written by Anneri Fourie | Crises Control Executive

When Things Go Wrong in Manufacturing

Manufacturing plants are complex systems with machinery, technology, and people working in close coordination. Any disruption can cause serious consequences if responses are uncoordinated or delayed.

Incident management software provides a centralised way to spot, respond to, and resolve incidents fast. By keeping communication clear, tracking actions in real time, and assigning responsibility, plants can protect staff, maintain production, and meet safety standards.

Understanding the Risks

Manufacturing facilities face a wide variety of potential incidents, including:

Cyberattacks

Modern production relies heavily on connected systems for inventory, quality control, and operations. Malware or unauthorised access can disrupt processes, compromise sensitive data, and even create safety hazards if automated machinery malfunctions.

Chemical Spills and Safety Hazards

Plants that handle chemicals or heavy machinery are at risk of accidents. Quick communication and coordinated responses are essential to prevent injuries, environmental damage, or regulatory violations.

Equipment Failures

Machines can break down without warning, causing production delays, missed deadlines, and extra repair costs. Without real-time updates, fixing these issues can take longer, affecting the entire operation.

Many manufacturers still rely on phone calls, emails, or manual logs to handle incidents. These methods are slow, error-prone, and do not give a complete picture of what’s happening across teams or shifts.

Turning Chaos into Control with Incident Management Software

Incident management software for manufacturing plants brings all incident reporting, communication, and response into one place. Here’s how it strengthens resilience:

Real-Time Incident Oversight

Managers can see what is happening across the plant immediately. Notifications, updates, and task assignments appear in real time, allowing teams to act quickly and prevent miscommunication. This visibility helps keep operations running smoothly.

Coordinated Response Across Teams

Different teams need to work together during incidents. The software ensures everyone knows their role, tracks their actions, and completes tasks without confusion or duplication.

Automatic Escalation and Accountability

If a message goes unacknowledged, alerts are automatically escalated to backup personnel or senior management. This prevents incidents from being ignored and ensures accountability at every level.

Documentation and Reporting

Every step is logged automatically. These records support compliance audits, internal reviews, and post-incident analysis, helping plants identify recurring issues and improve safety protocols.

How Incident Management Software Works in Real Life

Responding to Cyber Incidents

When unusual activity is detected on IT systems, the software sends instant alerts to the right staff. This coordinated response protects both operational systems and sensitive data, reducing downtime and preventing further disruption.

Chemical Spill Alerts

Sensors or monitoring systems can trigger automatic alerts in case of a spill. Staff receive clear instructions on evacuation and containment, while management tracks responses to ensure everyone is safe.

Equipment or Production Line Failures

If a machine fails, operational teams are notified immediately. The software assigns technicians, tracks repair steps, and monitors completion, minimising downtime and keeping production schedules on track.

Using these features, manufacturers shift from reactive incident handling to proactive management, reducing risks to staff, production, and reputation.

How Manufacturers Use Incident Management Software for Resilience

Plants that invest in incident management software gain multiple advantages:

- Faster Decision-Making: With real-time information, managers can prioritise actions quickly and effectively.

- Clear Communication: Multi-channel notifications reach all staff, contractors, and management consistently and accurately.

- Improved Safety: Structured workflows and automated alerts reduce the chance of accidents or regulatory violations.

- Operational Continuity: Coordinated responses ensure production keeps moving even during incidents.

- Post-Incident Learning: Detailed reporting highlights what worked, what didn’t, and how processes can be improved for the future.

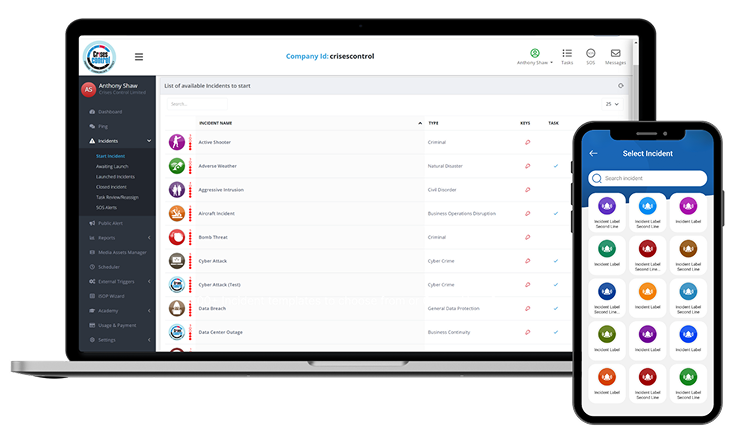

Interested in our Incident Management Software?

Launch and manage incidents in seconds with real-time dashboards, task management, multi-channel alerts, and mobile access for seamless response.

How Can Crises Control Help

Crises Control supports manufacturers at every stage of incident management, combining real-time alerts, task coordination, and reporting into a single platform. Plants can map high-risk areas for cyber threats, chemical hazards, or equipment failures and assign predefined response workflows to the right teams. Multi-channel alerts ensure that all relevant staff receive notifications instantly via SMS, email, app, phone calls. Microsoft Teams, or desktop messages.

Regular simulations allow teams to practise emergency procedures, while post-incident reporting highlights areas for improvement, helping manufacturers refine their response times, safety measures, and overall resilience.

For example, if a chemical spill occurs, Crises Control alerts all affected personnel immediately, communicates evacuation instructions clearly, dispatches and tracks clean-up crews, and gives supervisors full visibility to monitor and adjust responses. This ensures incidents are contained quickly, staff stay safe, and operational disruption is minimised.

By centralising incident reporting, streamlining coordination, and providing complete visibility of ongoing events and personnel, Crises Control enables manufacturers to maintain operational continuity, protect their workforce, and safeguard production even during complex crises.

Take Action to Strengthen Your Plant

Cyberattacks, chemical spills, and equipment failures are constant threats. Relying on outdated methods or fragmented communication puts staff, operations, and compliance at risk.

Incident management software gives manufacturers the ability to respond quickly, coordinate teams, and maintain operational continuity. Crises Control’s platform offers real-time incident tracking, mass notifications, and task management designed for manufacturing environments.

Book a free demo today to see how Crises Control can help your plant respond to incidents efficiently, protect personnel, and strengthen resilience.

Request a FREE Demo