Written by Anneri Fourie | Crises Control Executive

Factories are busy, noisy and fast moving environments. Machines run at full capacity, forklifts weave between stations, and workers across different shifts move through large areas with varied levels of visibility and access to information. When something goes wrong, many organisations realise that their current communication tools are not built for the speed, accuracy and clarity that manufacturing sites demand. A small fire, a sudden equipment failure or a chemical leak can create confusion if people do not receive the right information quickly enough. The problem is simple. Workers cannot respond to an incident they do not know about, and unclear communication often leads to hesitation, delays or unsafe choices.

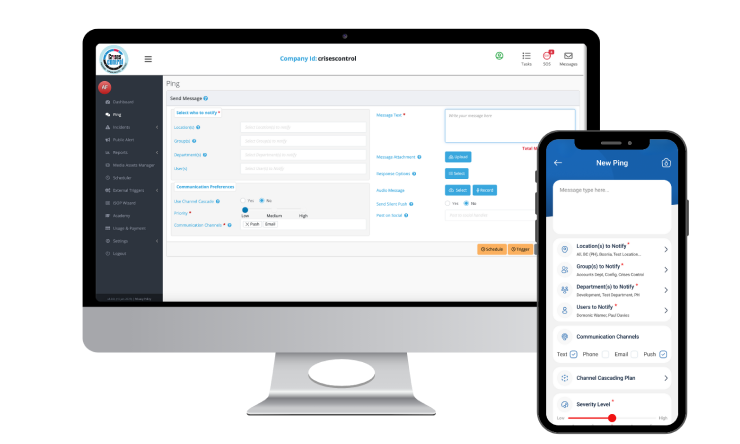

The solution requires more than a loudspeaker or a group email. A modern factory needs a way to reach everyone at once, across distance, noise, languages and roles. This is where a purpose built system helps. Mass Notification Software brings structure to communication, guiding the right alerts to the right people, confirming their status, and giving managers a clear view of what is happening in real time. In this blog, we explore what this looks like on a factory floor, why it matters and how Crises Control supports manufacturing teams who need faster, clearer and more reliable ways to warn, inform and guide their workers.

Why factories need stronger communication tools

Manufacturing sites are unique. A warehouse team faces different risks from a paint line operator. Welders work in areas filled with sparks and noise. Packaging teams often face high foot traffic and moving vehicles. Communication has to work in these diverse conditions, and many traditional tools fall short.

Public address systems struggle with clarity because machinery noise masks alerts. Radios reach only a subset of staff and require someone to be available to respond. Emails rely on desk access, which most factory workers do not have. Many organisations still rely on runners or supervisors relaying information verbally, which slows the response and introduces the risk of human error.

When you consider the range of incidents that can take place, from machinery faults and equipment fires to gas leaks, supply chain failures, severe weather, security problems or power issues, it becomes clear that a more structured method is needed. Fast delivery, confirmation of receipt and clear instructions can prevent secondary incidents and reduce downtime.

What should be included in an effective emergency response plan for factories

An emergency response plan for a manufacturing facility must be practical and easy for workers to follow. It should be written with the realities of a factory floor in mind, not only boardroom theory. A solid plan includes clear notification procedures, assigned roles, evacuation routes, assembly points, shutdown instructions and safety steps for specific hazards. It must also cover communication expectations for all teams, including contractors, cleaners, agency workers and visitors.

One critical part of an emergency response plan is the method for alerting workers. This should not rely on a single tool. A strong communication process uses layered channels so that if one method is blocked, another reaches the person. Mass notification is becoming a key part of this. It supports SMS, email, phone calls, desktop pop ups, mobile push messages and integrations with factory systems. This gives organisations confidence that messages will reach people even if they are moving, wearing hearing protection or working away from their desks.

The plan should also require regular drills. Manufacturing teams cannot rely on memory alone. Routine exercises test communication speed, identify gaps and give supervisors confidence that their workers know what to do. Many organisations run drills on Crises Control to track confirmation rates and identify teams that need more support or training.

Mass Notification Software in action on the factory floor

To understand why the technology matters, it helps to picture what happens during a real incident.

Imagine a production line machine overheating. A manufacturing plant with an integrated alerting system could receive an automated trigger from a temperature sensor. This sensor can send a signal directly into the notification system. As soon as that signal arrives, a pre configured alert can reach maintenance teams, supervisors, safety officers and affected workers. The message can include the zone, the recommended actions and whether the area needs to be cleared. This removes hesitation, avoids manual communication delays and gives managers an immediate view of who has responded.

Now consider a chemical leak in a mixing area. Time is critical and clarity prevents people from walking into danger. A mass notification system can target only the zones near the leak, guiding workers to safe routes while informing the rest of the site to avoid the area. This prevents panic and keeps the factory organised.

A different example involves power instability or electrical faults. When a plant experiences a sudden power dip, workers need to know if they should pause machinery, move away from equipment or follow evacuation steps. Multi channel alerts reach workers quickly and provide clear instruction instead of vague warnings.

Each scenario demonstrates how structured messages reduce confusion, improve coordination and create a safer environment.

How to notify factory workers during an emergency

Manufacturers face a frequent challenge. They must reach a large group of workers with very different communication needs. Some staff operate machines and cannot check their phones often. Some work in noisy zones where alarms are difficult to hear. Others move throughout the building and may not stay in one area.

Mass notification technology supports a range of contact methods so that alerts meet workers where they are. Common methods include SMS for quick visibility, phone calls for urgent situations, mobile app alerts for detailed instructions, email for documentation and desktop pop ups for office and control room teams. In some factories, loudspeaker tones or strobe lights work well when connected to the system.

This approach removes reliance on a single communication path. It also reduces the risk of delayed awareness. Instead of asking supervisors to manually relay instructions, the system sends messages instantly and waits for staff to confirm they have received them. Managers can see who is safe, who needs help and who has not replied. This visibility builds confidence and supports a faster response.

Mass Notification Software as a key tool in Manufacturing

Manufacturers increasingly expect their communication tools to support daily operations, not just emergencies. Many use mass notification to send planned shutdown instructions, notify staff of maintenance windows, communicate shift changes or inform workers of access restrictions around specific areas.

When workers receive clear instruction before maintenance or testing, plants reduce downtime and improve throughput. This helps them stay aligned with safety practices while keeping production on track. The system is also helpful during planned drills. Supervisors can measure participation and see how quickly teams respond to simulated alerts.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Why a Factory Emergency Communication System must support multilingual alerts

Many factories employ workers from across different regions and language backgrounds. Clear communication must reach everyone, not only those fluent in the main language used in the workplace.

A factory emergency communication system that supports multilingual alerts solves this issue. Crises Control allows organisations to send alerts in multiple languages, including English, French, Polish, Turkish, Arabic and Italian, so that workers receive instructions they can fully understand. This avoids confusion and supports compliance with safety rules. It also creates a more inclusive environment where no worker is left unsure about the steps they should take.

Automating alerts with sensors and industrial systems

Manufacturing plants have invested heavily in sensors, automation tools and SCADA systems. Connecting these devices to a mass notification system creates a seamless communication loop. A sensor can detect a threshold breach, such as rising gas levels or unsafe temperatures. It can then trigger alerts instantly without waiting for human verification.

For example, if a detector in the paint line identifies fumes above a safe level, it can send an automatic trigger to the communication platform. The system can then send alerts to affected zones, guide workers to the correct exit route and notify the safety manager to investigate. This type of automation reduces delays and supports a coordinated response.

Choosing the best emergency communication system for manufacturing plants

When organisations look for the best emergency communication system for manufacturing plants, they usually evaluate several factors. These include speed of message delivery, ease of use, integration options, mobile capability, reporting features, multilingual support and the ability to target specific groups or zones.

They also look for platforms that remain available even if their main IT services experience problems. Crises Control operates on its own cloud infrastructure, which continues functioning even if other cloud platforms face outages. This gives manufacturers confidence that their emergency communication tools remain available at all times. Many factories operate outside standard business hours, and they need systems that perform reliably across night shifts, weekends and public holidays.

Reporting is another consideration. After an incident or drill, managers need to understand who received alerts, who responded and where delays occurred. A platform that tracks this information helps improve future planning and training.

How Crises Control helps manufacturing sites strengthen worker safety

Crises Control supports manufacturing plants by providing a central system that can warn, guide and coordinate workers during disruptions. It offers multi channel alerts, automated triggers, two way communication, multilingual messaging, detailed reporting and mobile friendly tools. Organisations use it to support both emergency situations and everyday operational communication.

By adopting structured alerts, plants reduce confusion and shorten response times. Workers know what to do, managers know who is safe, and supervisors can focus on the incident rather than chasing information. This creates a safer and more organised site where decisions are based on real time facts, not assumptions.

Bring your factory from reactive to prepared

Clear communication is one of the strongest ways to protect workers and keep production moving. Manufacturing sites cannot rely on a single tool or informal processes when incidents occur. A structured system supports better coordination, improves awareness and helps workers act with confidence.

If you want to strengthen incident communication in your plant, you can explore how Crises Control supports factories across the world. To learn more or to see the system in action, contact our team to get a free personalised demo.

Request a FREE Demo