Written by Anneri Fourie | Crises Control Executive

The Cost of Silence When Machinery Fails

A line goes silent. A warning light flashes. Your lead engineer is off-site. No one is sure who’s in charge. And now the entire shift is standing around waiting for instructions.

This is not just a technical hiccup. It’s the start of a very expensive hour.

Unplanned downtime in manufacturing can cost tens of thousands of pounds per hour. But the financial impact is only part of the problem. Delays in response can lead to missed orders, safety risks, and even regulatory penalties. When a critical piece of equipment fails, your team doesn’t just need information, they need instructions, clarity and speed.

That’s where mass notification software steps in. More than just sending alerts, it helps you activate your response plan immediately, get the right people on task, and keep everything moving, even in the middle of chaos.

Let’s look at how Crises Control helps manufacturers turn those crucial first 60 minutes into an organised, effective response.

Why Machinery Malfunctions Disrupt More Than Just Output

In manufacturing, machines are the heartbeat of operations. When one fails, the ripple effects can be severe and immediate:

- Worker safety risks: Equipment failures can cause injuries, fires or chemical exposure if not managed quickly.

- Downtime losses: Stalled production lines lead to missed SLAs and contractual penalties.

- Uncertainty: Staff often don’t know what to do, who to tell or where the procedures are.

- Compliance risks: Delayed or incorrect responses could result in regulatory breaches.

The challenge is not just fixing the machine. It’s getting the right people involved, following the correct steps and documenting every action in real time.

Traditional tools like radios, internal phone calls or printed procedures simply can’t keep up. That’s why many manufacturers now rely on digital mass notification systems to coordinate their response from the moment something goes wrong.

What Is Mass Notification Software and How Does It Help in a Crisis?

Mass notification software is a digital platform that sends messages to specific people or teams through multiple channels at once; SMS, mobile push alerts, email, voice calls, desktop pop-ups and more.

But in an industrial environment, it does more than just send messages. It acts as a real-time response engine.

With Crises Control, you can pre-build incident templates for different scenarios. So when a machine overheats, a hydraulic system fails or a conveyor belt shuts down, you’re not starting from scratch. The software kicks off a sequence of alerts, instructions and escalations automatically.

In short, it helps your people take the right action, without delay.

Inside the Golden Hour: How Crises Control Guides Every Step

Here’s how Crises Control supports your team during that critical first hour after a major equipment failure.

1. Immediate Trigger and Incident Launch

An incident can be triggered by a sensor, a manual input or a routine check. Once triggered, the platform launches the specific response plan tied to that type of failure. You can customise these for different systems, like power outages, hydraulic leaks or equipment jams.

This means your team isn’t guessing. They’re following a tested, automated plan from the start.

2. Role-Based Alerts and Smart Escalation

Instead of alerting everyone, Crises Control sends messages to the people who actually need to know. The safety officer. The engineering lead. The maintenance technician. Each receives an alert through multiple channels at once.

If someone doesn’t respond within a set time, the system automatically notifies the next person in the chain. Nothing gets missed, and no time is wasted chasing responses.

3. Task Automation and SOP Activation

Once the alert is out, the software assigns tasks linked to your standard operating procedures. For example:

- Isolate the faulty equipment

- Evacuate the area if needed

- Disable connected systems

- Begin diagnostic checks

- Log incident details

Each task is tracked, so managers can see progress in real time and follow up where needed.

4. Live Collaboration and Situation Room

All communication and updates are centralised in a virtual control center. Teams can update statuses, share photos or documents and keep everyone on the same page, even across multiple sites or shifts.

This replaces messy message chains or trying to track actions over the phone.

5. Full Audit Trail and Compliance Records

Every action is logged. Who was notified, when they responded, what they did and when they completed it. This is crucial for regulatory compliance, insurance claims and internal audits.

You don’t need to piece together emails or paperwork later. It’s all ready and exportable from the system.

Crises Control vs. Traditional Methods: What’s the Difference?

| Traditional Tools | Crises Control |

| Only reaches a few people | Notifies the right people, instantly and across channels |

| Manual escalation | Automatically escalates based on role and response time |

| Disconnected from procedures | Links directly to incident templates and SOPs |

| No visibility | Real-time dashboards and task tracking |

| No record keeping | Full audit trail and reporting features |

The difference is not just speed—it’s structure. Crises Control replaces confusion with clarity, every time.

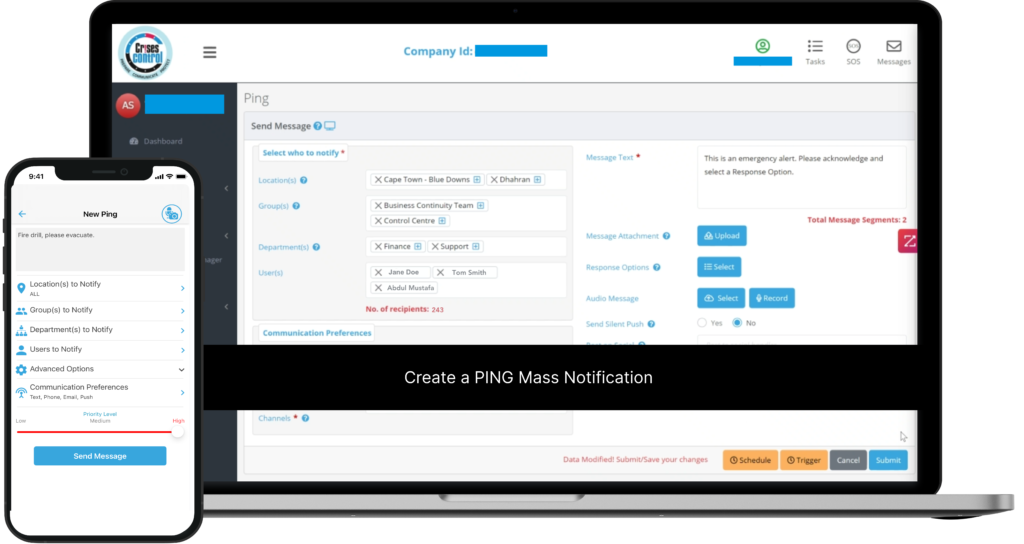

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software – PING, get the message out fast and ensure rapid response and recovery.

Smarter Alerts Through Integration

Crises Control can connect directly to industrial systems and building management platforms.

You can configure automatic triggers based on:

- Temperature thresholds

- Vibration patterns

- Pressure changes

- Electrical surges

This means your machines don’t just fail, they tell you they’re about to. And your response begins before a person even gets involved.

Long-Term Gains Beyond Just Emergency Response

Mass notification software doesn’t just help in emergencies. It improves how your entire team thinks about safety, operations and communication.

- Boosts safety culture: People know what to do and feel more confident in emergencies.

- Streamlines training: You can run simulations and train teams using the same system.

- Improves reporting: Everything is documented and ready for audits.

- Supports resilience: When disruptions happen, you’re ready to adapt, not just react.

The result is a stronger, safer, more responsive workplace.

Build Your Own Golden Hour Playbook

Want to make the most of Crises Control? Here’s a quick setup checklist for your plant:

- Identify your most common failure types

- Create custom incident templates for each

- Define who needs to be alerted in each case

- Link each template to your SOPs

- Connect alerts to sensors or monitoring systems

- Schedule quarterly drills and reviews

By planning ahead, your team can act confidently and effectively when it matters most.

Conclusion: Be Ready for Your Next Machine Failure

You can’t prevent every malfunction. But you can control what happens next.

With Crises Control’s mass notification software, you can respond to machinery failures and workplace accidents in minutes, not hours. You reduce downtime, protect your people and stay fully compliant, all while keeping your plant running smoothly.

Want to see it in action?

Contact us today for a free demo of Crises Control and take the first step towards mastering your Golden Hour.

Request a FREE Demo