Written by Anneri Fourie | Crises Control Executive

Mining sites are some of the toughest places to manage during an emergency. You have workers spread across pits, haul roads, processing plants, underground tunnels, workshops and remote satellite sites. Communication is always a challenge, and during a crisis, the difficulty increases. When a gas leak, equipment fire, ground movement or severe weather alert hits, the biggest risk is not only the hazard itself, but the delay in reaching the people who need to act.

The problem many mining companies face is that their communication tools were never designed for time-sensitive, high-risk situations. Radios and emails have limitations, public address systems do not reach every area, and manual call trees slow everything down. A single break in the chain can leave teams unaware of what is happening, which increases danger for both frontline workers and maintenance crews.

This is where a smart digital communication platform that sends fast, reliable and site-wide alerts becomes part of the solution. Mass Notification Software gives mining companies a way to warn, inform and direct people during emergencies without relying on a single communication method. The result is faster awareness, better coordination and clearer instructions when mistakes carry real consequences.

This blog explains what effective crisis management looks like in the mining sector, why communication gaps often occur, and how a platform such as Crises Control supports safer, more coordinated emergency response across entire mining operations.

Why communication failures happen in mining environments

Mining sites face pressures that are very different from most industries. These pressures often turn small delays into serious safety threats. The main challenges include:

1. Multiple work zones with poor signal reach

Mining teams rarely operate in one location. Workers move between pits, blasting areas, control rooms, workshops and offices. Underground tunnels create blind spots where radios and mobile networks struggle.

2. Round-the-clock operations

Mining continues at all hours. During night shifts, skeleton crews often work with fewer supervisors on site. A slower response at these times increases the severity of an incident.

3. High machinery noise levels

Heavy equipment, blasting, ventilation systems and haul trucks create noise that masks alarms and prevents people from hearing verbal instructions.

4. Harsh physical environments

Dust, vibration, moisture and heat all affect the reliability of on-site devices. Even small outages can delay critical messages.

5. Lost time during escalation

When a supervisor needs to reach managers, emergency teams, security and control room staff, they often rely on manual steps. Every extra step adds minutes to the response.

These challenges make fast, multi-channel communication essential. If alerts do not reach people instantly and reliably, the site’s ability to control an incident becomes limited.

How Mass Notification Software supports strong crisis management in mining

Mass Notification Software gives mining companies a single platform that sends alerts through several channels at once. This avoids delays caused by failed radio calls or limited coverage.

A well designed system does far more than push notifications. It helps teams coordinate, confirm receipt of alerts, follow predefined steps and maintain a complete record of the event.

Below are the core capabilities that matter most for mining operations and the practical outcomes they deliver.

- Multi-channel delivery: Alerts reach staff by mobile app, SMS, voice calls, email and browser notifications. If one channel fails, the others still deliver the message. This improves reach across remote areas and underground shifts.

- Two-way communication: Workers can respond to messages, report their status, confirm instructions and request help. This removes guesswork for supervisors and control rooms.

- Automated escalation: If the first group does not respond within a set timeframe, the system automatically escalates to the next team. This ensures key decision makers never remain unaware of a threat.

- Prebuilt emergency workflows: Mining incidents require structured steps. A gas leak, fall of ground or conveyor belt fire all demand rapid action. Workflows guide teams through each stage so no task is forgotten.

- Real time tracking: Supervisors see who has received the alert, who has responded and who may be at risk, which supports safer evacuations and faster accountability.

- Integration with existing systems: Modern mining relies on SCADA, monitoring sensors, ventilation alarms and access control systems. Mass Notification Software can trigger alerts automatically when readings spike or equipment conditions change.

- Offline capability: Where mobile signal is weak, the Crises Control app continues to operate using local device storage and synchronises when a connection returns. This is especially important for underground teams.

These functions are not only technical features. They solve real safety problems. They shorten the time it takes to warn teams, they prevent instructions from being lost and they help coordinate crews who are often hundreds of metres apart.

Creating an effective emergency response plan for mining sites

Mining companies know they need emergency plans, but plans only work when people understand them and when communication is clear. A strong plan has several characteristics:

- Hazards are clearly identified: This includes gas exposure, fall of ground, vehicle collisions, fires, structural instability, tailings failures, blasting misfires and severe weather. Each hazard needs its own communication and response steps.

- Incident roles are assigned: Every plan should identify who is responsible for site control, who manages first aid, who monitors evacuation routes, who contacts external services and who maintains communication records.

- Information flows are mapped: A good plan defines how an alert travels from detection to the people who must act. If the route is unclear, the risk increases.

- Communication tools are tested: Plans must match the tools in use. If a radio fails in a certain tunnel or a siren cannot be heard at a remote loader pad, the communication plan must compensate.

- Staff receive clear instructions: Workers need simple, direct steps to follow. For example, evacuate to Muster Point B, isolate equipment, shut down ventilation, or move to the refuge chamber.

- The plan is accessible: If the plan is stored in binders or paper files, crews cannot reach it quickly. A digital version ensures staff always have access through their phone or device.

Technology cannot replace training, but it can remove confusion during the response. The more automatic and structured the communication, the less chance there is of mistakes.

Why mining companies need regular business continuity drills

Many mining companies write emergency plans, but fewer run structured drills often enough. Drills are critical because mine conditions change daily. New contractors arrive, infrastructure changes, weather shifts, and new hazards appear.

Regular drills help identify weaknesses such as:

- Evacuation routes that take too long

- Workers unclear about their roles

- Gaps in radio coverage

- Supervisors unsure of who to notify first

- Delays caused by manual messaging

- Muster points not suitable for certain weather conditions

Drills also build confidence. When crews practise alerts through Mass Notification Software, they learn how quickly messages travel, how to confirm receipt and how to report their status. This reduces confusion during real emergencies.

Crises Control supports drill scheduling, automated reminders, performance tracking and post drill reporting. This helps mining companies meet regulatory requirements and measure improvement over time.

A scenario that shows the difference

Imagine a gas sensor detects abnormal readings during a night shift. Only a small team is working underground. Traditionally, a supervisor might radio the control room. The control room then calls managers. Managers then try to reach workers through separate channels.

This chain takes time, and the first message may not reach everyone.

With a mass notification system:

- The alert triggers as soon as the sensor crosses a threshold.

- The control room is notified instantly.

- All workers in the affected zone receive app notifications, voice calls and SMS at the same time.

- Workers confirm receipt with a single tap.

- The system escalates to supervisors if someone does not respond.

- Evacuation instructions are issued and tracked.

- The control room sees in real time who is moving to safety.

This approach reduces confusion, shortens delays and gives managers clear visibility of team safety.

How Crises Control supports mining operations

Crises Control provides an emergency communication platform designed for businesses that need to reach people quickly and reliably. Several strengths make it well suited for mining sites:

- Operates across low connectivity zones: The mobile app keeps working even when coverage is poor, which is often the case in underground tunnels or remote open pit areas.

- Multi channel communication: The system sends alerts by app notification, SMS, voice call, Microsoft Teams and email. This improves successful delivery across noisy and dispersed worksites.

- Automation that removes delays: The platform automates escalation, task assignment, response collection and reporting. This reduces the chance of human error.

- Integration with safety systems: Crises Control can integrate with sensors and monitoring tools used in mining, giving companies a way to trigger automatic alerts when conditions change.

- Independent cloud infrastructure: Crises Control operates on its own cloud, so the system continues working even if external platforms face outages. The app ensures teams can still receive alerts during wider service disruptions.

- Clear reporting and audit trails: Every alert, action and response is recorded. This helps with regulatory audits, safety investigations and continuous improvement.

- Fast onboarding: New staff, contractors and visitors can be added quickly. Training is simple, with clear user steps and a straightforward app layout.

These features help mining companies reduce emergency response times, increase awareness on site and maintain communication accuracy even during complex incidents.

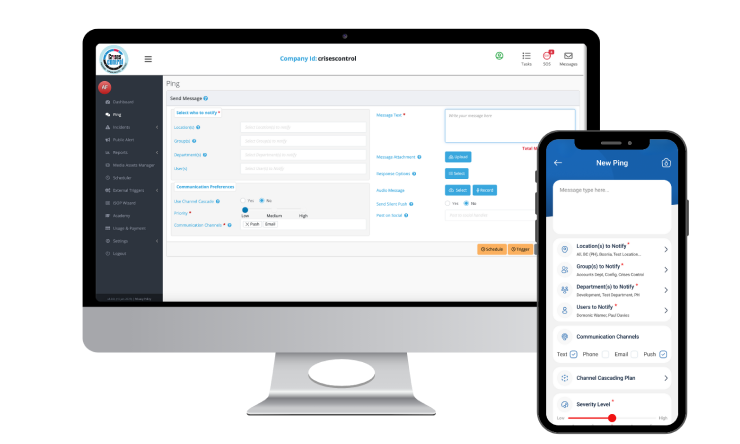

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Comparison table: Traditional methods vs digital emergency communication

| Communication method | Limitations | Benefits of Mass Notification Software |

| Radios | Limited range, channel interference, underground blind spots | Multi channel delivery reaches more people instantly |

| Phone trees | Slow, manual and dependent on one person making calls | Automated alerts sent to thousands in seconds |

| Public address systems | Noise interference from machinery | Alerts reach workers even in loud environments |

| Email only | Delays during night shifts or remote work | SMS, voice, email and app notifications ensure faster delivery |

| Paper based plans | Hard to access during a crisis | Digital plans available on mobile devices anytime |

This comparison highlights how digital communication improves consistency and reach, especially on large, noisy, multi level mining sites.

Strengthening your emergency response strategy

Mining companies face high risk daily. Communication is one of the few factors that can be fully controlled, tested and improved. Mass Notification Software gives mining organisations a way to share critical information quickly, direct teams with confidence and reduce the impact of unexpected events.

If you want to explore how Crises Control supports mining companies with emergency communication, automated workflows and structured incident response, you can contact our team to get a free demo.

Request a FREE Demo