Written by Anneri Fourie | Crises Control Executive

Why Business Continuity Still Fails in Oil and Gas, and How Mass Notification Software can Help

In oil and gas, the margin for error is incredibly small. From offshore rigs and refineries to transportation and distribution networks, operations are often high-risk, complex, and geographically spread out. When something goes wrong, and it often does, time is critical.

Many organisations invest heavily in Business Continuity Planning (BCP), but plans alone aren’t enough. What tends to break down is the response, and more specifically, the way teams communicate during a crisis. That’s where the cracks start to show.

The truth is, a large number of companies in the energy sector continue to rely on outdated, manual systems for emergency communication. As a result, even small incidents can spiral into serious disruptions. Staff don’t receive instructions quickly enough. Decision-makers lack real-time information. Critical stakeholders are left out of the loop.

The solution isn’t just another plan on paper. It’s a reliable communication platform that can bring the plan to life, quickly, clearly, and in real time.

This blog explores the most common BCP mistakes seen in the oil and gas sector and how using mass notification software like Crises Control can make the difference between control and chaos.

The Importance of Business Continuity in Oil and Gas

Business continuity in oil and gas is not a “nice to have”, it’s a critical function that protects lives, safeguards infrastructure, and keeps operations running when things go wrong.

Whether dealing with a gas leak, cyber attack, equipment malfunction, or severe weather, companies need to act fast and coordinate effectively. But without a reliable way to communicate across departments, locations, and time zones, those efforts are often disjointed or delayed.

What’s needed is not just a plan, but a system that supports action.

The Most Common BCP Mistakes in Oil and Gas Companies

1. Relying on Manual or Outdated Communication Tools

Many companies still depend on phone trees, mass emails, or basic SMS alerts to contact teams during emergencies. These methods are slow, easy to break, and hard to manage at scale.

What can go wrong:

In an incident, delays in communication can leave frontline workers uncertain about what to do. Managers may not know who has received updates. Critical instructions may be missed entirely.

What to do instead:

Mass notification software like Crises Control allows organisations to send alerts instantly across multiple channels – text, email, phone call, mobile app, Microsoft Teams and even desktop pop-ups. Messages are tracked, confirmed, and targeted based on role, location, or department.

2. Failing to Test and Update the Business Continuity Plan

Writing a BCP is one thing. Keeping it relevant and effective is another. Plans often sit untouched for years, only to fall apart when actually needed.

What can go wrong:

Staff may not know their roles. Contact details may be out of date. Systems that seemed fine on paper don’t work in practice.

What to do instead:

Crises Control includes tools for running simulations and tests. You can rehearse different scenarios, gather feedback, and improve your processes before a real crisis hits. You also get automatic reminders to review and update plans at regular intervals.

3. Fragmented Incident Response Across Teams

In a crisis, different departments often operate in silos. Facilities, IT, HR, security, and leadership may each have their own systems or procedures, which makes coordination difficult.

What can go wrong:

You end up with conflicting information, duplicated efforts, and missed steps. No one has a full picture of what’s happening or what needs to be done next.

What to do instead:

Crises Control creates a centralised hub where incidents can be logged, tracked, and resolved. It brings all teams together with one version of the truth, assigning tasks, monitoring progress, and escalating issues automatically when needed.

4. Poor Communication with External Stakeholders

It’s not just internal staff who need clear updates during a crisis. Regulators, supply chain partners, local authorities, and the public may all require accurate, timely information.

What can go wrong:

Inconsistent or delayed messaging can damage trust, cause reputational harm, and even lead to regulatory penalties.

What to do instead:

Mass notification software allows you to create and store message templates in advance. These can be sent to stakeholders in moments, with clear records for audit and compliance purposes. You can also target messages based on geography, stakeholder group, or incident type.

5. Overlooking Cyber Threats in Continuity Planning

The energy sector is a prime target for cyber attacks, particularly those that aim to disrupt industrial control systems. But many BCPs still focus too heavily on physical risks.

What can go wrong:

A ransomware attack can lock teams out of critical systems. Without remote access to communication tools, coordination grinds to a halt.

What to do instead:

Crises Control is cloud-based, which means you can access it securely from any device with internet access, even if internal systems are compromised. It also supports two-way communication, allowing staff to report issues or confirm safety statuses in real time.

Why Mass Notification Software Is Essential for the Oil and Gas Sector

When emergencies strike, speed, clarity, and reach are essential. Mass notification software gives you all three.

Key capabilities that oil and gas companies should look for:

- Multi-channel delivery: Send alerts through multiple methods at once to ensure maximum coverage.

- Two-way communication: Request acknowledgements, gather responses, or receive live updates from staff.

- Automation: Trigger alerts automatically based on sensor data, thresholds, or third-party integrations.

- Geo-targeting: Send messages only to affected teams or locations to reduce unnecessary noise.

- Audit trail: Maintain detailed records for internal review and regulatory reporting.

These features don’t just help manage crises better, they reduce the chances of a crisis turning into a disaster.

How Crises Control Supports Oil and Gas Resilience

Crises Control is designed specifically for organisations operating in high-risk, regulated environments. While it’s suitable for many industries, it’s particularly well-suited to the complex needs of the oil and gas sector.

Key features include:

- Automated alerts: Create pre-approved messages for different incident types that can be sent instantly.

- Scenario planning: Build playbooks for various emergencies, from facility fires to cyber threats.

- Real-time dashboards: Monitor incidents, responses, and staff safety from one central hub.

- Task tracking: Assign roles and responsibilities with deadlines and automatic escalations.

- Mobile access: Ensure remote and offshore teams can stay connected wherever they are.

- Security and compliance: End-to-end encryption, full GDPR compliance, and high availability.

The platform helps teams shift from reacting to preparing, making continuity planning a strength, not a gap.

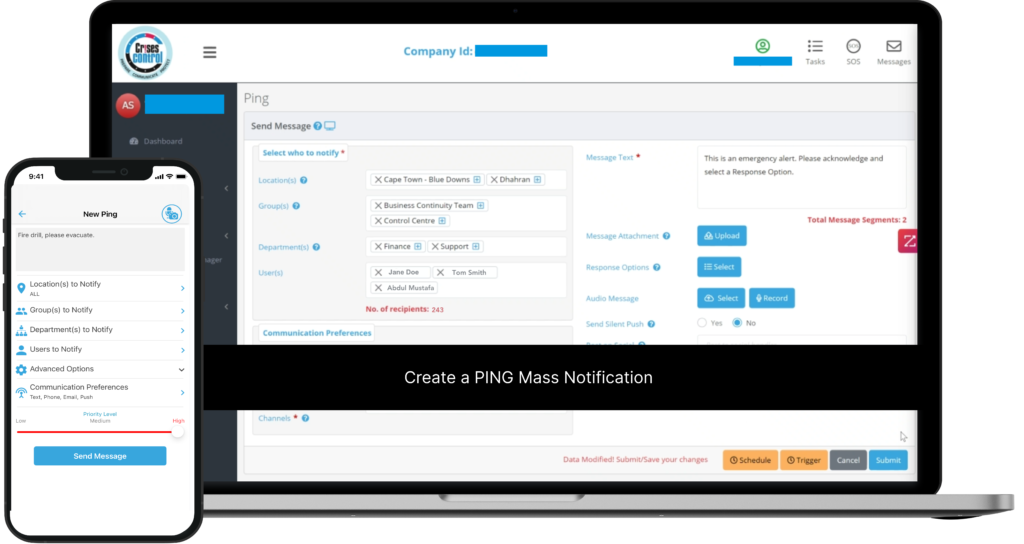

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software – PING, get the message out fast and ensure rapid response and recovery.

Best Practices for Oil and Gas Emergency Alerts

To make the most of your communication strategy, consider the following tips:

- Standardise protocols: Use message templates to ensure consistency across teams and incidents.

- Empower local teams: Train frontline workers to trigger alerts and take immediate action.

- Review regularly: After each incident or drill, evaluate what worked and what didn’t.

- Use location data: Avoid alert fatigue by targeting only those who need the information.

- Connect systems: Integrate your alert platform with access control, HR, and monitoring tools for faster reactions.

Final Thoughts: Communication is the Real Continuity Plan

A crisis can happen at any moment. When it does, the strength of your communication tools will often determine how well your organisation responds.

Business continuity in oil and gas isn’t just about writing detailed documents. It’s about making sure your teams can act quickly, stay informed, and work together, even under extreme pressure.

Crises Control gives you the tools to make that happen. It’s not just about sending alerts. It’s about building confidence, reducing downtime, and protecting what matters most.

Get Your Free Demo

If you’re ready to close the gaps in your crisis response and strengthen your business continuity strategy, we invite you to try Crises Control for yourself.

Contact us today to book a free demo

Request a FREE Demo