Written by Asipe Nokenke | Marketing Assistant

In 2023, the global supply chain disruption cost businesses over $4 trillion. Logistics companies are particularly vulnerable: a single delayed shipment can ripple across warehouses, clients, and suppliers, leading to lost revenue and reputational damage.

This is why supply chain disruption notifications and incident management for logistics companies are no longer optional; they are essential. By integrating tools that combine alerts and incident handling, companies can act faster, make informed decisions, and prevent minor delays from becoming major crises.

1. Transport and Transit Disruptions

Transport issues remain the most frequent cause of supply chain delays. From road closures and vehicle breakdowns to port congestion and extreme weather, bottlenecks ripple through every stage of logistics.

Scenario: A lorry carrying pharmaceutical products from Rotterdam to London hits a traffic closure due to flooding. Without real-time alerts, warehouse staff and clients remain unaware, potentially leading to stockouts and regulatory breaches.

How to Prepare:

- Implement supply chain disruption notifications to alert drivers, warehouse managers, and clients instantly.

- Use incident management for logistics companies to assign tasks and monitor rerouting options.

- Predict risks by analysing historical transit data and developing pre-mapped alternative routes.

Benefit: Minimises downtime and ensures critical shipments arrive on time, even in unexpected conditions.

2. Supplier or Manufacturing Delays

A PwC survey found that 76% of organisations reported their most serious disruption had a medium-to-high impact on operations, disrupting critical business processes and causing downstream financial and reputational issues. For logistics companies, supplier-related disruptions, whether due to raw material shortages, production breakdowns, or quality control failures, can quickly halt operations even when transport networks are running smoothly.

Scenario: A UK-based electronics manufacturer depends on components from three suppliers. When one experiences a production breakdown, the entire production line risks grinding to a halt, threatening delivery schedules.

How to Prepare:

- Supplier risk scoring: Maintain a dashboard that scores suppliers by reliability, financial health, and delivery history.

- Early-warning alerts: Use emergency supply chain management to send notifications if a supplier misses production milestones.

- Diversification strategy: Build secondary supplier contracts into your disruption preparedness plan to avoid over-reliance on one provider.

Benefit: Ensures continuity even when primary suppliers underperform, reducing downtime and risk.

3. Regulatory and Compliance Interruptions

Cross-border shipments are particularly vulnerable to customs and regulatory hurdles. Delays caused by incomplete paperwork, shifting trade regulations, or stricter inspections can lead to significant disruption and costs.

Scenario: A shipment of medical equipment to an EU country is held due to incomplete paperwork. Without instant notifications, the warehouse and client remain unaware, potentially impacting patient care.

How to Prepare:

- Integrate supply chain disruption notifications into compliance workflows.

- Track and resolve clearance issues in real-time using incident management for logistics companies.

- Conduct regular audits and train staff to reduce documentation errors.

Benefit: Reduces fines, ensures timely delivery, and maintains client trust.

4. IT and System Failures

Digital infrastructure is the nervous system of logistics. When systems fail, communication, tracking, and operations are paralysed.

Scenario: An online retailer relies on automated warehouse software. A system outage prevents order tracking and inventory updates, leaving staff unable to fulfil customer orders.

How to Prepare:

- Implement a crisis communication platform that continues operating even if the main IT systems fail.

- Develop SOPs within incident management for logistics companies to guide rapid recovery.

- Conduct regular IT audits and maintain backup systems.

Benefit: Protects operations and maintains visibility during outages, ensuring rapid recovery.

5. Natural Disasters and Extreme Weather

Climate-related events are becoming increasingly disruptive, from severe snowstorms and floods to hurricanes and wildfires. These events can wipe out entire transport corridors in hours.

Scenario: Severe snowfall closes roads in northern Germany, halting deliveries of perishable goods. Without supply chain disruption notifications, warehouses cannot adjust schedules or reroute deliveries.

How to Prepare:

- Use real-time alerts to notify field teams and stakeholders immediately.

- Develop disruption preparedness plans with alternative routes, storage, and emergency contacts.

- Coordinate responses using combined notification & incident management tools for logistics.

Benefit: Minimises operational downtime and preserves supply chain reliability.

How Crises Control Supports Logistics Companies

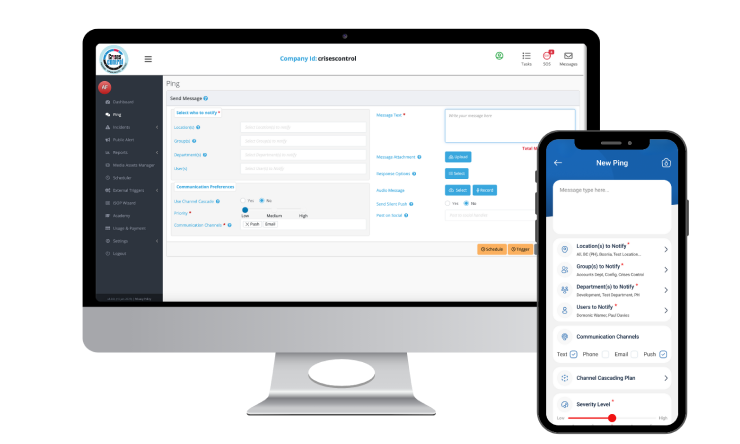

Crises Control’s Ping and Incident Manager combine proactive alerts with incident handling, giving logistics companies a complete solution for emergency supply chain management:

- Notify staff, suppliers, and clients instantly across multiple channels.

- Assign and track responsibilities in real-time, ensuring swift resolution.

- Maintain detailed audit trails for compliance reporting.

- Standardise responses with SOPs and escalation rules to reduce human error.

With Crises Control, logistics teams can respond to disruptions confidently, preventing minor issues from escalating into major crises.

Interested in our Ping Mass Notification Software?

Efficiently alert everyone in seconds at scale with our Mass Notification Software.

Best Practices for Disruption Preparedness

- Implement combined notification & incident management systems: Avoid fragmented communication.

- Conduct scenario-based drills: Test your emergency supply chain management plans regularly.

- Map critical supply routes and suppliers: Identify vulnerabilities before they cause disruptions.

- Train staff on SOPs: Ensure clarity in roles and responsibilities during crises.

- Maintain real-time communication: Use a crisis communication platform to coordinate every stakeholder instantly.

These practices, combined with Crises Control, help logistics companies stay ahead of disruptions and maintain seamless operations.

Conclusion

Supply chain disruptions are inevitable, but their impact can be mitigated with proactive planning and technology. By implementing supply chain disruption notifications and incident management for logistics companies, businesses can respond faster, reduce losses, and maintain client trust.

Crises Control empowers logistics teams with Ping and Incident Manager, combining alerts and incident handling to ensure operational continuity.

Contact us today for a free demo and see how your supply chain can stay resilient, no matter the disruption.

Request a FREE Demo